New cut-to-length line improves performance at Alfun

Heinrich Georg Maschinenfabrik recently commissioned a hybrid cut-to-length line for aluminum, steel and stainless steel strip at the Alfun Metal Service Center located in Bruntál in the Czech Republic. The new line includes a high-precision side trimming unit. The high degree of automation and numerous other advanced design features achieve exceptionally high productivity.

阅读文章

Strip line upgrade implemented entirely via remote connection

When planning the upgrade of Hulamin’s No. 5 cut-to-length line into a multi-purpose line that would additionally be able to recoil and side-trim the strip, nobody expected this project to become an extraordinary challenge.

阅读文章

Heinrich Georg Maschinenfabrik strengthens digital service

New organizational structure puts stronger emphasis on service activities, providing customers additional opportunities for productivity improvement.

阅读文章

New GEORG high-performance leveller in operation at EMW Steel Service Center

Six-high machine excels in levelling high-strength steels

Kreuztal, Germany, 12 January 2021 …

阅读文章

New machine concept combines optimum surface quality with minimum assembly time

“Ex stock”-supplied roll grinder achieves excellent results at AMAG.

Kreuztal, Germany, 26 November…

阅读文章

GEORG: Germany’s best Machine Builder

Awarded top employer for the third year in a row

(Kreuztal). The Kreuztal-based company has…

阅读文章

Germany's most family-friendly company in the field of mechanical engineering

Great pleasure at GEORG.

(Kreuztal). It is not the first time that the Buschhüttener family…

阅读文章

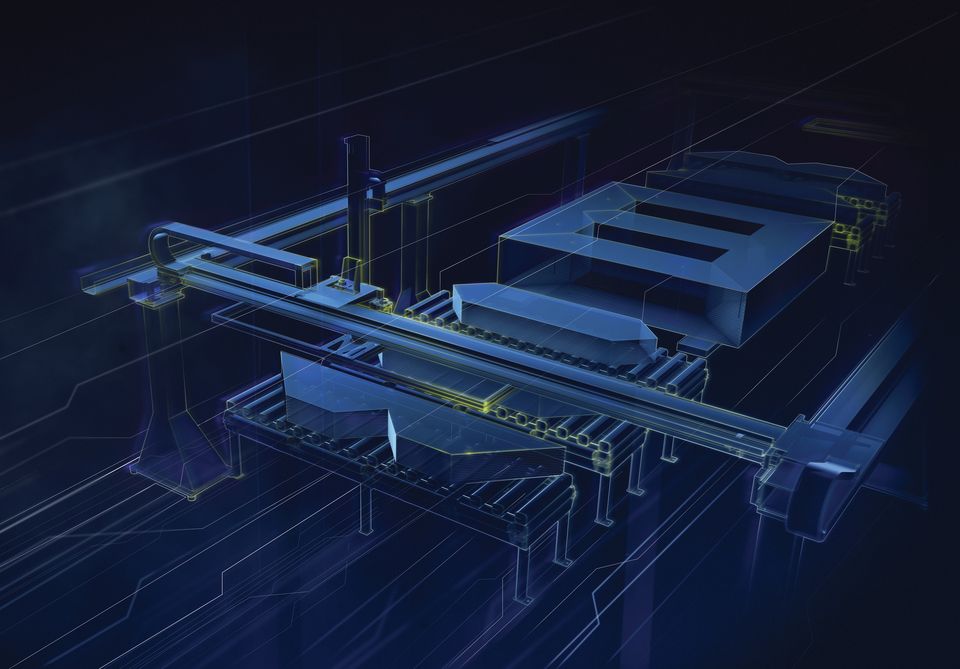

World premiere at EMO 2019: The digital twin has become real.

Georg has implemented the first digital twin with the new “Sinumerik ONE” CNC software.

Kreuztal,…

阅读文章

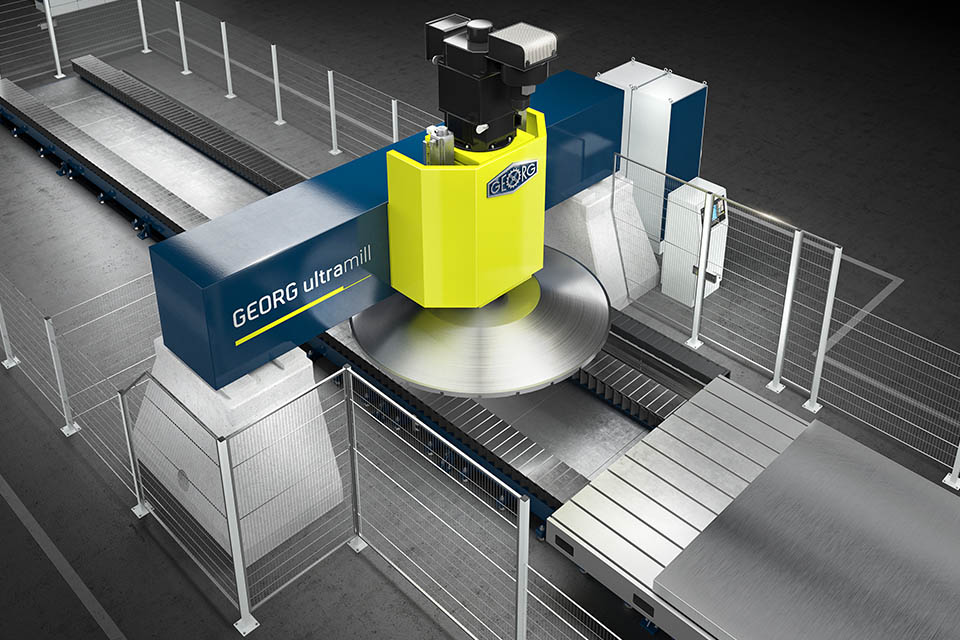

The first fully automatic milling machine for aluminium ingots

Highly automated system cuts machining-cycle times by more than 30 percent.

Kreuztal, Germany, 29…

阅读文章

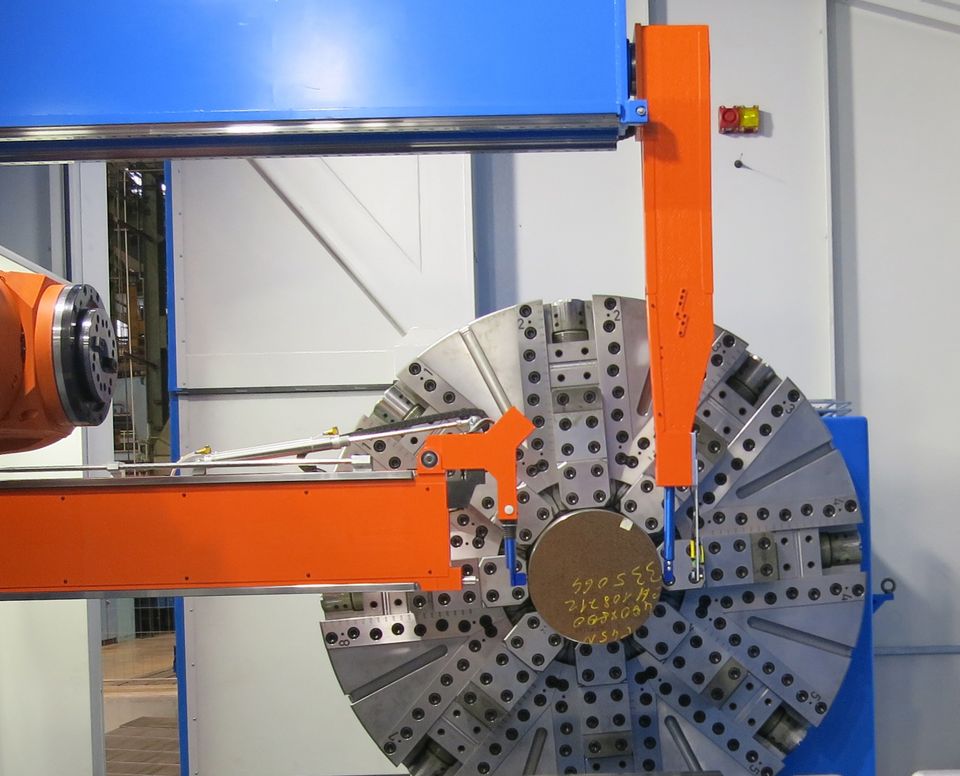

Automatic adjustment of separator shafts reduces unproductive downtimes

Setting-up of separator shafts now simply at the push of a button.

Kreuztal, Germany, 3 July 2019…

阅读文章

Press facts for FIEE 2019

Inline and offline stacking systems use the potential of digitalization

Kreuztal, Germany, June 7,…

阅读文章

GEORG and HIT enter into a strategic cooperation

Autonomous low-floor transport vehicles for the intralogistical transport of heavy loads

Driverless…

阅读文章

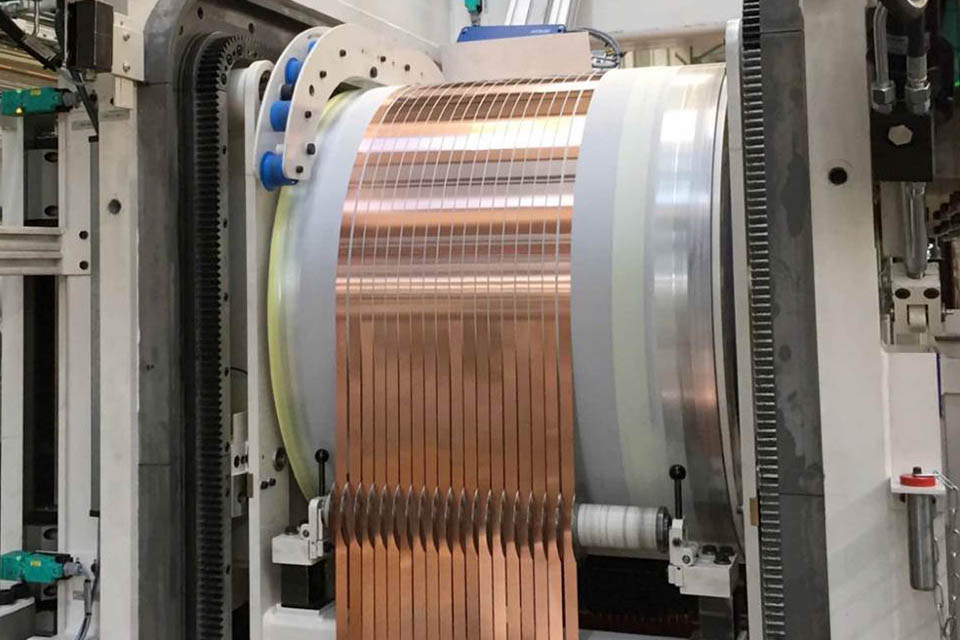

First roll grinding machine using CBN abrasives

New technology cuts machining times and extends service life of rolls

The GEORG ultragrind 25 roll…

阅读文章

First roll grinding machine for aluminum rolling mills using CBN technology

New grinding technology cuts machining time by half.

At the Aluminium 2018 show in Düsseldorf,…

阅读文章

“Please do not touch” – Vacuum protects the good side

New vacuum technology guarantees high surface quality

Kreuztal, Germany, 4 December 2018 At the…

阅读文章

From machine builder to process optimizer

At the occasion of an in-house exhibition Heinrich Georg GmbH demonstrated its innovative power and…

阅读文章

Milling machine for aluminium plates sets new standard

Highly automated system cuts machining time by more than 30 percent.

At the Aluminium 2018 show in…

阅读文章

Neutralizing the CO2-Footprint

Climate change and climate protection? At GEORG these are not just only buzz words but they form…

阅读文章

New slitting line for Eisen + Stahl Service Center

Kreuztal, Germany, August 10, 2017 GEORG has received an order to manufacture and supply a new slitting line to the German steel service center E + S Eisen + Stahl Service GmbH. With the new line, the Mannheim-based company will be adding the sale of slit strip out of its own facilities to its portfolio, thus taking another important step towards metal product processing in addition to trading.

阅读文章

EMO 2017: Two-point measurement reduces non-productive times

At EMO, GEORG will be presenting the integrated two-point measurement system for horizontal machining centers of its ultraturn MC series. These machines process workpieces weighing 10 tons and more and with diameters of 1,000 mm upwards. No other manufacturer in the world combines machining and measuring in a single unit of such size.

阅读文章

Strategic cooperation between Georg and Güdel Group

Kreuztal/Langenthal, Germany, June 19, 2017 Heinrich Georg Maschinenfabrik and Güdel Group AG concluded a cooperation agreement for the collaborative development of lines for the automatic stacking of transformer cores. GEORG brings in their know-how in the plant engineering field, Güdel the robot technique for the automatic stacking of the laminations. That way, systems are constructed in the future that speed up the production of transformers, reduce manual time and enable a higher production flexibility. Furthermore, the intensive data transfer prepares the ground for industry 4.0 / IoT.

阅读文章

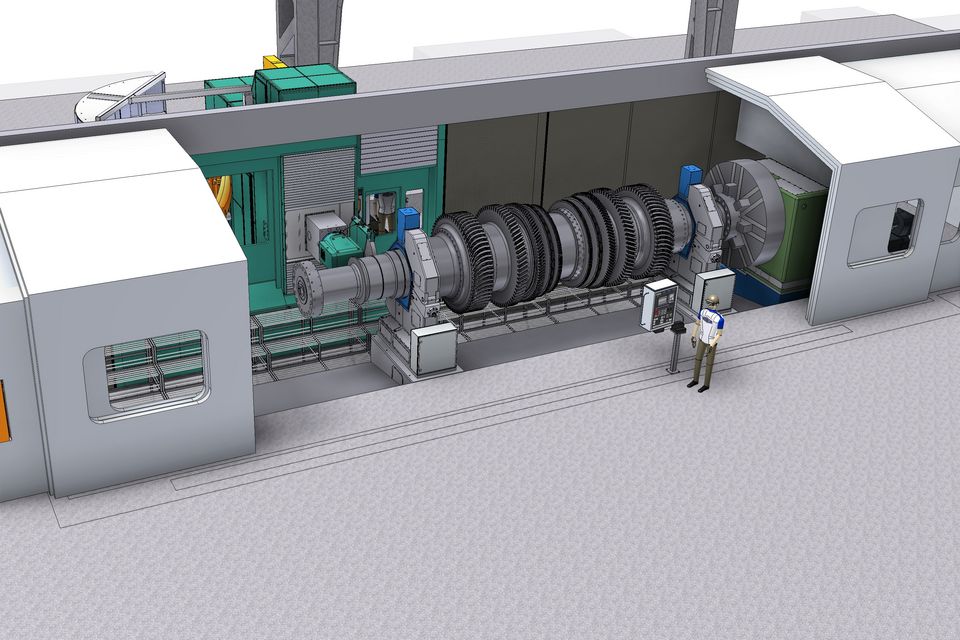

The “GEORG” machine cuts machining times at Doosan Škoda Power by 50 percent

Kreuztal, Germany, April 3, 2017 On February 28, Doosan Škoda Power officially inaugurated the new ultraturn MC horizontal machining center supplied by GEORG at its Pilsen works in the Czech Republic. Doosan Škoda Power will use the new machine primarily for machining turbine rotors of up to 140 tons weight. This machining center is the third of its kind in the world to combine turning, drilling, milling, grinding and measuring of extremely large parts in one unit.

阅读文章

New machining centers save 40 percent of machining time

At AMB GEORG presents the horizontal machining centers of the series ultraturn MC, which processes workpieces up to 250 tons and 4,000 mm diameter. With the successful commissioning of the first machine at Siemens AG in Berlin and installation of two additional machines GEORG is the world's only manufacturer of machining centers of this size which implements the concept of working and measuring on the same machine.

阅读文章

Heinrich Georg Maschinenfabrik delivers the fourth Roll Lathe to Trinec

Last December, Heinrich Georg GmbH Maschinenfabrik received an order for the delivery of a roll lathe for up to 10 t of workpiece weight from Czech company Strojirny a Stavby Trinec, a.s. This is already the fourth machine ordered in Kreuztal by the subsidiary of Třinecké železárny a.s. since 1996.

阅读文章

Heinrich Georg Maschinenfabrik: Leveller for plates of „excess width“

Kreuztal/Germany, June 8, 2015 In May GEORG delivered on schedule a levelling center for large-sized aluminium plates to a customer in Russia who is primarily a supplier for the aircraft industry. This machine has been designed for plates of up to 3.200 mm width and max. 12 m length. The heart of the line is the GEORG high-duty plate leveller RM 120 x 3200. Supported by precise measurement technology, GEORG achieves an ultimate flatness of plates during the levelling process, finally documenting a flatness accuracy in the hundredth millimeter range.

阅读文章

Heinrich Georg Maschinenfabrik reduces manufacturing time of large and complex workpieces by weeks

Kreuztal, Germany, 27. May 2015 On a customer day, GEORG introduced the new Machining Center “ultraturn MC” to manufacturing experts. More than 80 specialists of large part manufacturers came to Kreuztal to witness the premier of the new machine, which is able to handle workpieces from 12 up to 250 tons. The ultraturn MC offers plenty of innovations, which combine highest precision during the machining process with optimum productivity and flexibility. For such large-size parts, the machine reduces the manufacturing time by up to 40 per cent. The integrated 2-point-workpiece measuring system as well as the complete machine enclosure set new standards.

阅读文章

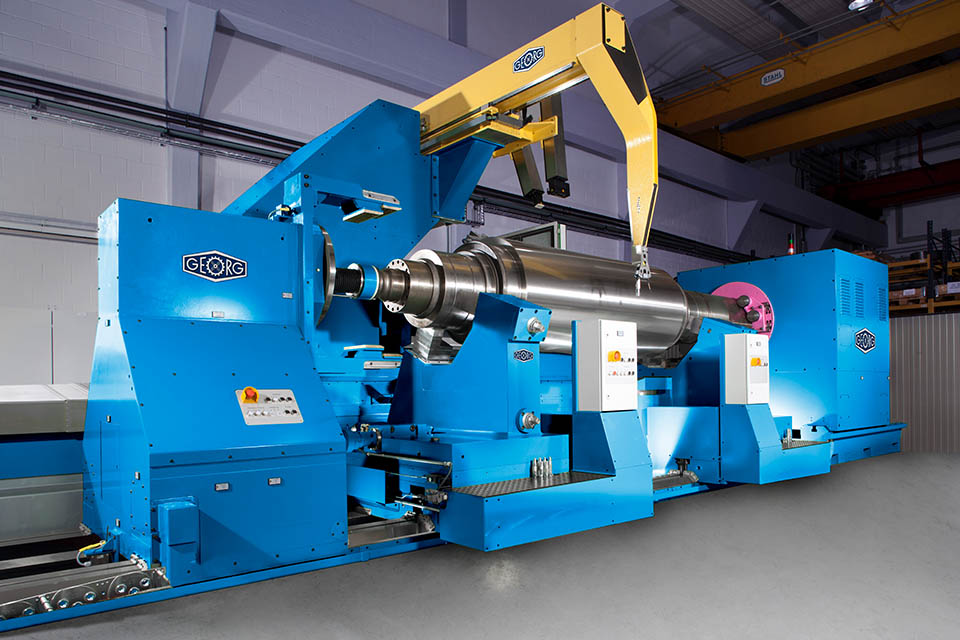

Heinrich Georg Maschinenfabrik: First roll grinder for cold mill rolls

Kreuztal, Germany, March 23, 2015. At the occasion of a customer day Georg presented its new roll grinding machine type ultragrind 700 R to an experienced audience. The new machine is designed for center lengths of 5.000 mm, grinding diameters of up to 700 mm and roll weights up to 10 tons. The machine works fully automatically and impresses by its high grinding qualities in conventional and CBN grinding. Due to many special design solutions, its very solid structure and innovative measuring technologies the machine achieves highest precision and at the same time shortest setting and machining cycles.

阅读文章

![[Translate to Chinesisch:] [Translate to Chinesisch:]](/fileadmin/_processed_/1/4/csm_GEO_remote-service_teaser_e22e5363d9.jpg)