乔格新闻中心

Strategic cooperation between Georg and Güdel Group

Kreuztal/Langenthal, Germany, June 19, 2017 Heinrich Georg Maschinenfabrik and Güdel Group AG concluded a cooperation agreement for the collaborative development of lines for the automatic stacking of transformer cores. GEORG brings in their know-how in the plant engineering field, Güdel the robot technique for the automatic stacking of the laminations. That way, systems are constructed in the future that speed up the production of transformers, reduce manual time and enable a higher production flexibility. Furthermore, the intensive data transfer prepares the ground for industry 4.0 / IoT.

GEORG is leading in the manufacture of production lines for the transformer industry and already has own automation solutions. However, for the manufacture of power and big distribution transformers of up to several hundred tons, many GEORG customer often still stack the individual laminations for the transformer cores manually which is very time consuming. The potential of modern handling systems and the networking of data often remains unused so far. Especially for offline systems, there are only few highly automated systems.

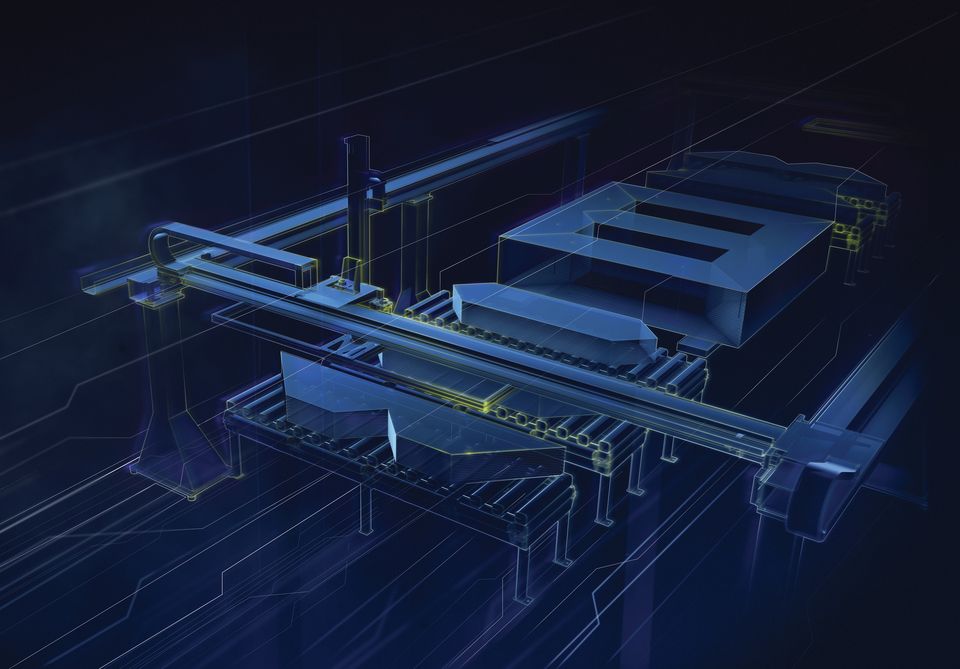

On the basis of their gantry robot, Güdel has already developed an automatic core stacking system for transformers in the 50 kg to 350 tons weight range which was put into operation at a leading European transformer manufacturer. The in-house manufactured gantry robots do not require any external centering units thanks to their high positioning accuracy and repeatability and thus reach significantly lower production times.

With their leading technologies, Güdel Group realises solutions for motion tasks in the individual automation. Martin Sträb, CEO of Güdel Group, emphasises “we will be able to work out even better automation solutions for the transformer industry together with our partner GEORG. The efficiency will be increased further and thereby also the satisfaction of our customers. I look forward to our collaborative work”.

GEORG brings in profound knowledge of the entire line technique in the transformer industry – from the decoiling of the strip from the coil over the cutting-to-length of the strip to the cutting of the laminations and the stacking of the cores. Güdel contributes the robot handling systems and the networking of the individual components among each other.

As there are several GEORG customers who cut ahead and stock laminations which they want to stack to a core with an offline system at a later stage, the focus for the first common projects will be the development of an offline system for the automatic stacking of transformer cores.

The laminations cut by the GEORG line and interim stored are picked up and stacked fully automatically by the Güdel robots. For the positioning, the robots achieve highest accuracies and beyond that accelerate the core stacking process significantly. The direct data transfer from the cutting line to the robot unit makes time-consuming manual processes redundant. By this data coupling, the new systems can be easily integrated into digitally networked environments and thus prepare the ground for industry 4.0 / IoT.

Bernd Peter Schmidt, Managing Director of the transformer business division at GEORG sees considerable benefits for his customers: “By the cooperation of our two companies – who both have an outstanding reputation in their respective field – we will deliver complete systems that make the stacking of the laminations much more effective. We make use of the vast experience and well-proven standard components of Güdel. This means for our customers: innovative and at the same time reliable technology with considerable cost advantages.”

Rocco Montalenti, General Manager Business Unit Technologies at Güdel relies on the market knowledge of GEORG: “For more than 30 years, GEORG manufactures transformer lines and has an impressive market share worldwide. The GEORG employees know the conditions in the transformer industry inside out. By this, we are able to elaborate single-source solutions together that are exactly adapted to the requirements of our common customers.”

The cooperation is in accordance with the philosophy of both companies to offer optimal solutions for smooth transformer production processes.

4.294 字符包括空格和前导字符