Cutting Line with a Perfect Finishing Touch

Coopertion between GEORG and Decomecc

Decomecc located in Genk/Belgium is a well known specialist in finishing of products from rolled aluminum. Starting from aluminum coils the Belgium company produces blanks and shaped sheets in high precision. For company founder Lambert Gerkens highest quality is always the target and a wide range of international customers appreciates this. E.g. aluminum mills whose customers manufacture build-up structures for trucks as well as tanks and storage containers purchase wide and thick aluminum plates from Decomecc.

Already early in the company’s history the cooperation with GEORG started. As a well-known manufacturer of cutting lines for wide material we could give useful information. Reference lines had been engineered and delivered to China and Russia with width of up to 2.800mm.Together we developed the first cutting line on the market equipped with a crank shaft swing shear for material with minimum thickness of 0,5 mm and a width of 2.300 mm for precise cutting of critical surface material.

“Cutting line of Superlatives”

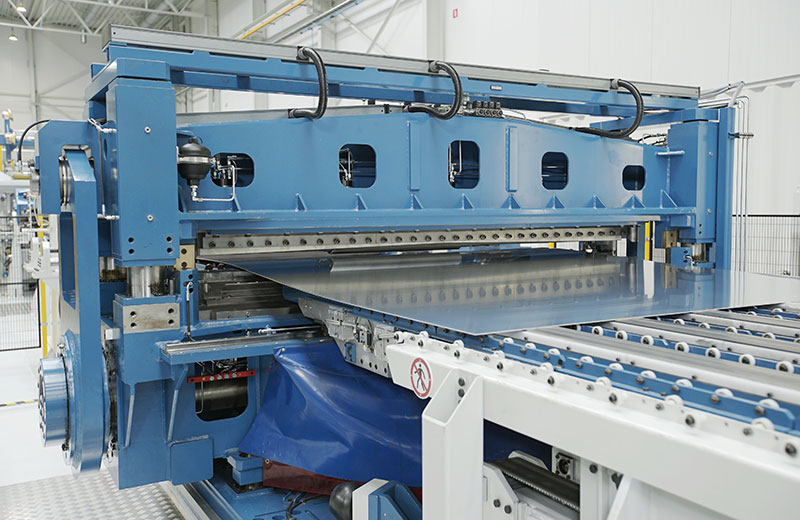

Driven by common experiences we decided in 2017 to design a new exclusive line for edge-trimming, high-precision leveling under highest tolerances, and precise, exact and careful cutting, stacking and packing of material exactly to customers’ orders. A high demand comes from the automotive sector. Sheet lengths of 8m and 2.300mm width are possible.

The material thickness ranges between 0,5 mm and 4,5mm. There is also a demand to finish very even scratch and dustfree blanks for automotive as well. Such sheet surfaces can be covered with dry lubricants like drylube or hotmelt. Therefore the line drive rolls have special coatings and the leveler is equipped with several quick change cassettes. When designing a cutting line for a service center a fast automized production for proper material and flexible process chains even of small batches has to be considered.

The magazine International Aluminium Journal named this line “ A Cutting line of Superlatives”. The GEORG line is located in a new built production hall which resembles a laboratory. To guarantee an absolute dustfree atmosphere the hall is set under overpressure and can only be accessed via pass-gates. The new line meets the requirements of the automotive industry. The leveler chosen is equipped with three different leveling cassettes instead of two normally in use. The third cassette with focus automotive is foreseen for leveling sheets with dry-lube and hot-melt coating within a thickness range of 0,8 – 2,5 mm.

The cutting shear has been designed as crankshaft swing shear with separated longitudinal and cutting stroke and enables cutting of rectangular and non-rectangular blanks. Even bow shapes and radial cuts are possible. Behind the cutting line a packing line has been arranged in order to stack the cut sheets automatically onto pallets. It only took a few weeks to bring the line into production mode for high grade blanks and today it runs at high capacity to the entire satisfaction of our customer.