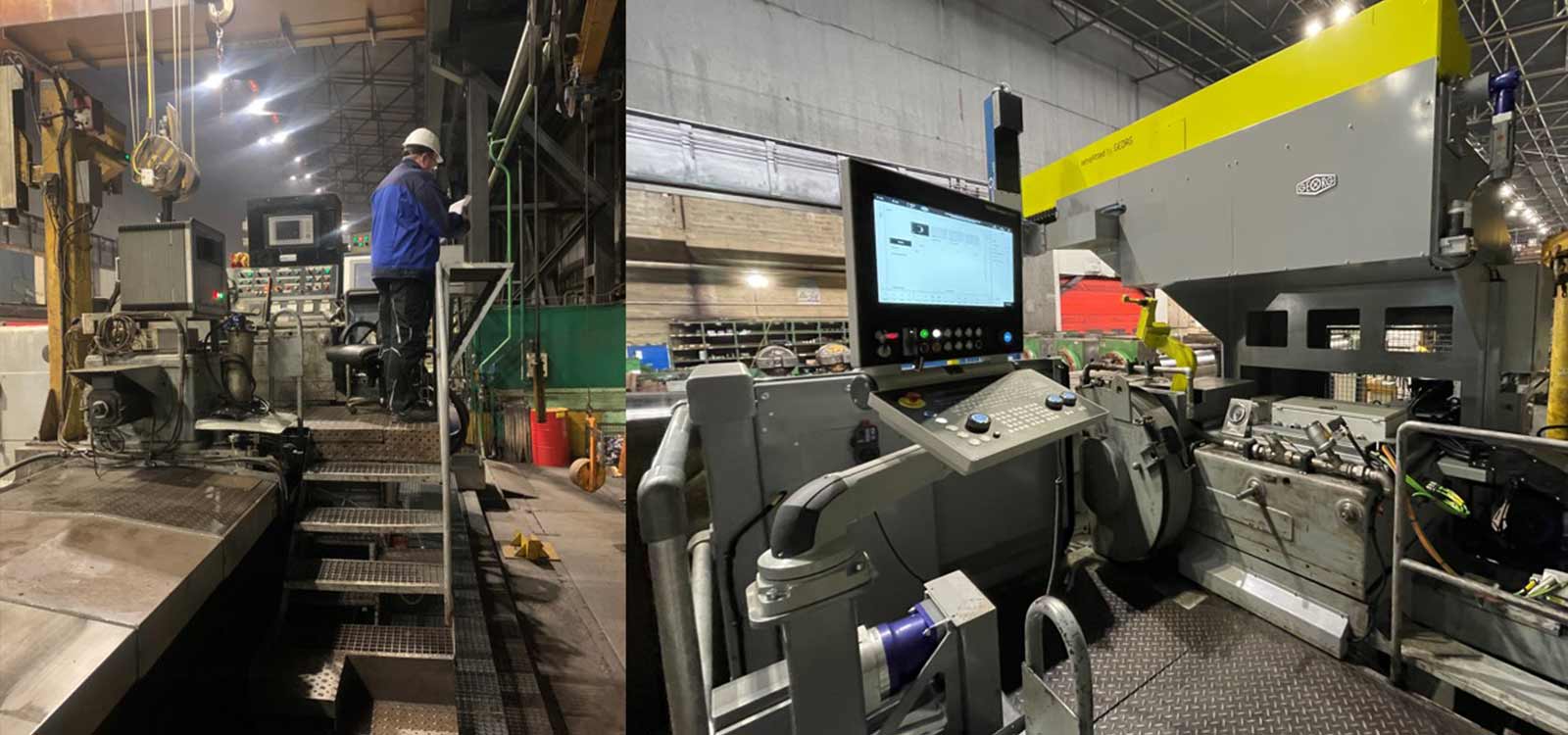

Successful retrofitted machine for Aperam

For our customer APERAM in Châtelet (Belgium), we have carried out an extensive retrofit of a 50-year-old roll grinding machine.

The machine was equipped with a new control system, GEORG smartcontrol, new drive motors and a completely new control cabinet including cabling.

For the first time, an automatic roller measuring system was retrofitted to the machine and the proven GEORG measuring caliber was installed. We also repaired and adapted other components.

Within four weeks, the required grinding of one roller per day could be implemented. Full processing capacity was achieved within six weeks, which is reflected in the customer's high level of satisfaction.

Project manager Marc Hendrik Althaus: "The GEORG team did everything they could to meet the customer's deadlines and expectations."

Old roll grinding machine before refurbishment

When can we modernize your roll grinding machine(s)?

Please do not hesitate to contact our service manager Stephan Müller:

+49(0)2732-779334