Sulzau-Werfen ironworks receives new GEORG ultragrind roll grinding machine

Eisenwerk Sulzau-Werfen, R. & E. Weinberger AG, founded in 1770, is one of the world's leading manufacturers of composite casting rolls for steel forming.

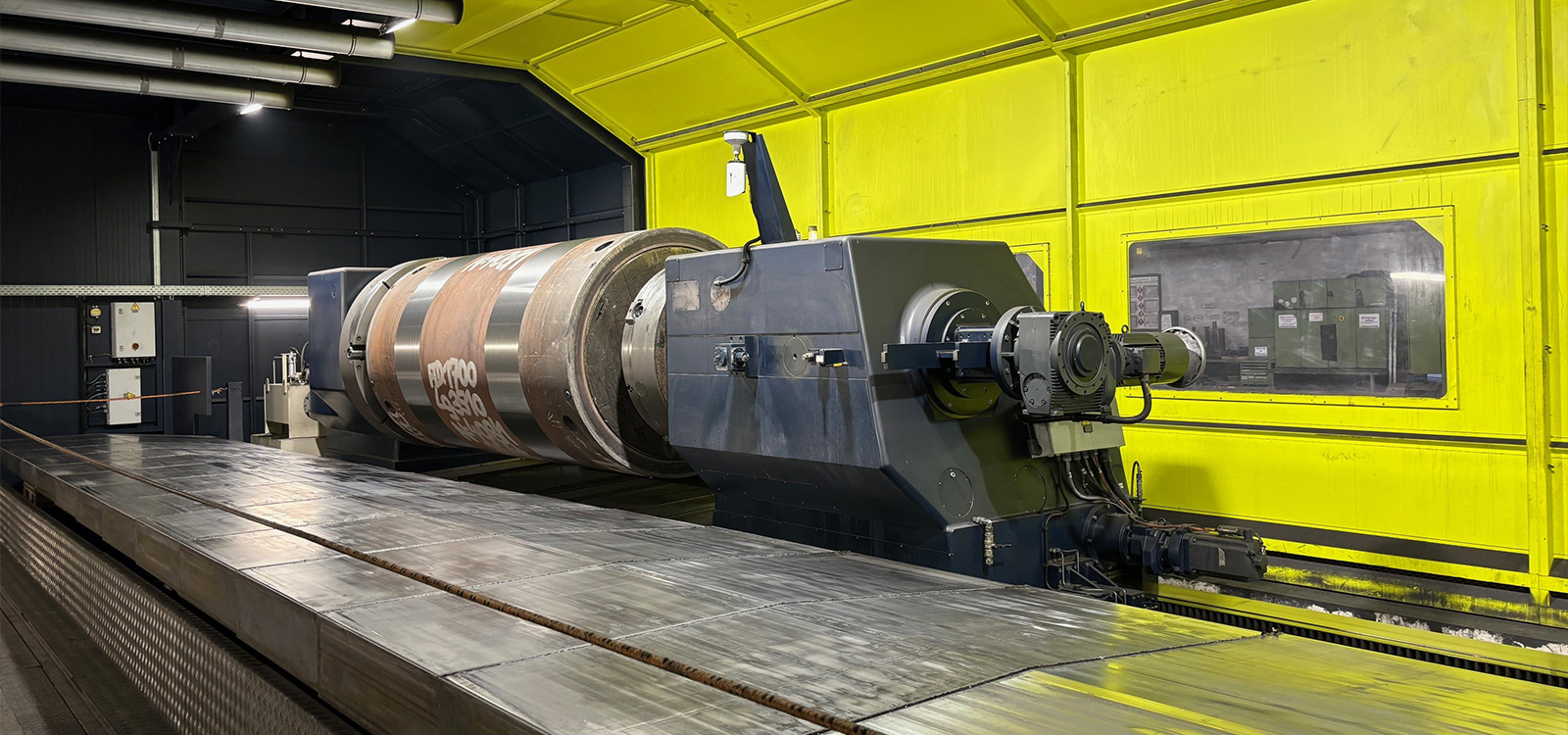

The roll grinding machine, which went into operation in spring 2023, continues the decades-long partnership between ESW and Heinrich GEORG GmbH. The most recently delivered GEORG ultragrind 60 grinding machine is already the third system from Kreuztal. High reliability and process safety as well as optimum long-term accuracy were of particular importance to ESW when purchasing the new GEORG machine.

Delighted with the commissioning of the new GEORG grinding machine at the Sulzau-Werfen ironworks (from left): Josef Aigner (Head of Mechanical Processing), CTO Michael Brandner, CEO Georg Hemetsberger and Raphael Vorderleitner (Deputy Head of Mechanical Processing).

The machine concept for processing workpieces up to a maximum weight of 60 tons and a diameter of 1.850 mm, with the "state of the art" GEORG smartcontrol control system, provides a first-class technological basis for future challenges.

With the powerful grinding carriage, the high-precision GEORG 3-point measuring system and the hydrostatic guides, the new GEORG machine creates ideal conditions for high performance when processing heavy work rolls as well as large casting molds.

"The health of our employees is an important factor and we consider permanent measures to further improve this to be a matter of course." This principle is enshrined in ESW's mission statement. In order to live up to this, the ultragrind 60 was supplied with a modern full enclosure with integrated high-performance extraction system.

We would like to thank you for the trust you have placed in our GEORG systems since 1998.