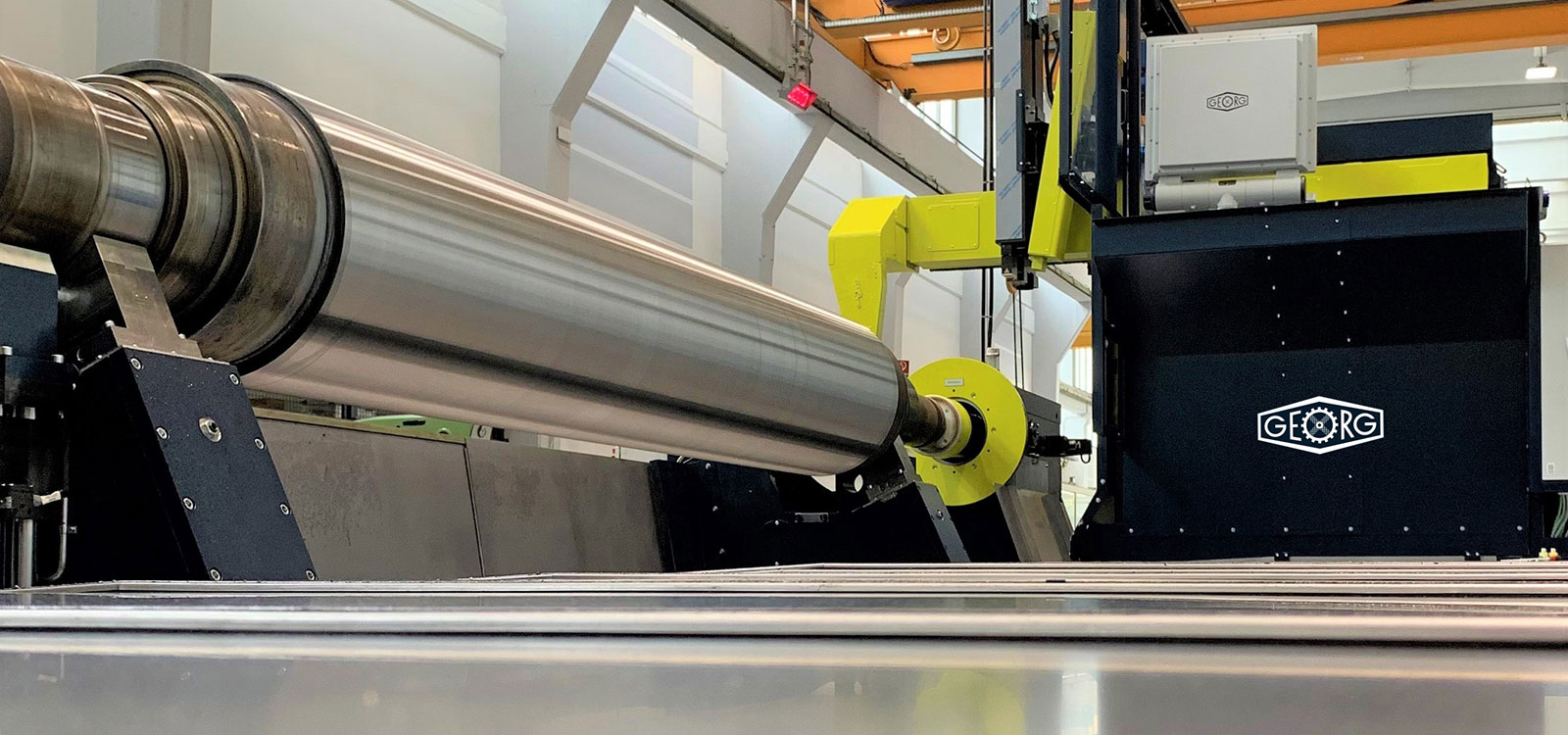

Next GEORG ultragrind 10 is ready for delivery

GEORG is currently delivering its tenth roll grinding machine type GEORG ultragrind 10. The machine is a work roll grinder for use in the automotive sector in China. The background to the investment is an increase in capacity in the customer's rolling mill from currently 1.5 million tons to then up to 2.0 million tons per year.

The machine is already equipped with the GEORG smartcontrol CNC system as standard. The GEORG smartcontrol forms the interface between man and machine.

Transferring the innovative possibilities in terms of ergonomics, interactivity and flexibility of smartphones, tablet PCs etc. to a machine tool was one of the main objectives in the development of the state-of-the-art control.

Due to the current zero covid policy in China, the challenge now is to ship the machine to China and assemble and commission it at the customer's site. Here we can rely on the support of our experienced service team in China.