Hitachi Energy orders new GEORG lines for power transformer core production

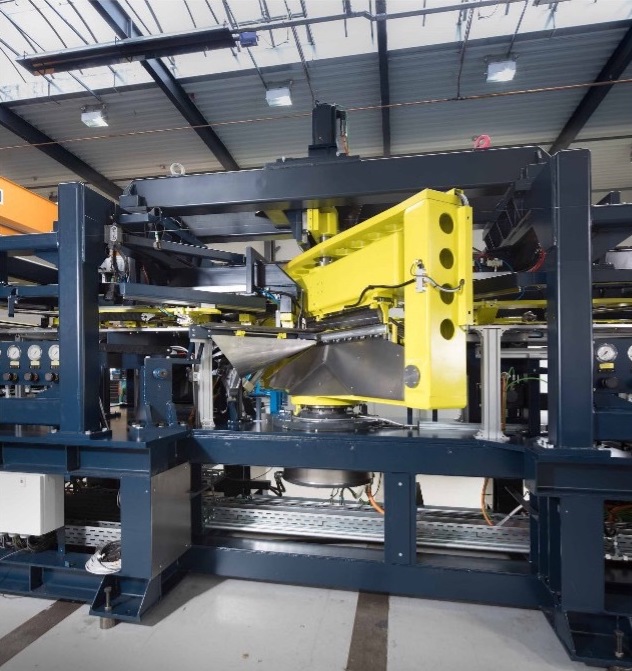

Hitachi Energy has ordered two new GEORG precisioncut TBA1000 S lines from GEORG for two of their plants.

Both machines will be equipped with the GEORG high speed swing shear, providing highest flexibility in power transformer core design.

One machine will be delivered to the plant in Chongqing, China while the other one is dedicated for the plant in Guarulhos, Brazil.

GEORG is very pleased about the strategic partnership with Hitachi Energy.

These new machines equipped with highly efficient drives contribute to the sustainable development goal of Hitachi Energy to reduce energy consumption and lower carbon emissions with eco-efficient processes.

Hitachi Energy (formerly ABB) now operates about 35 GEORG Step Lap Lamination Cutting Lines and another 10 machines (such as slitting and corrugated tank wall production lines) supplied by GEORG also dedicated to the transformer production in various plants all around the world.