ABB and GEORG

GEORG is proud of the great trust rendered by ABB

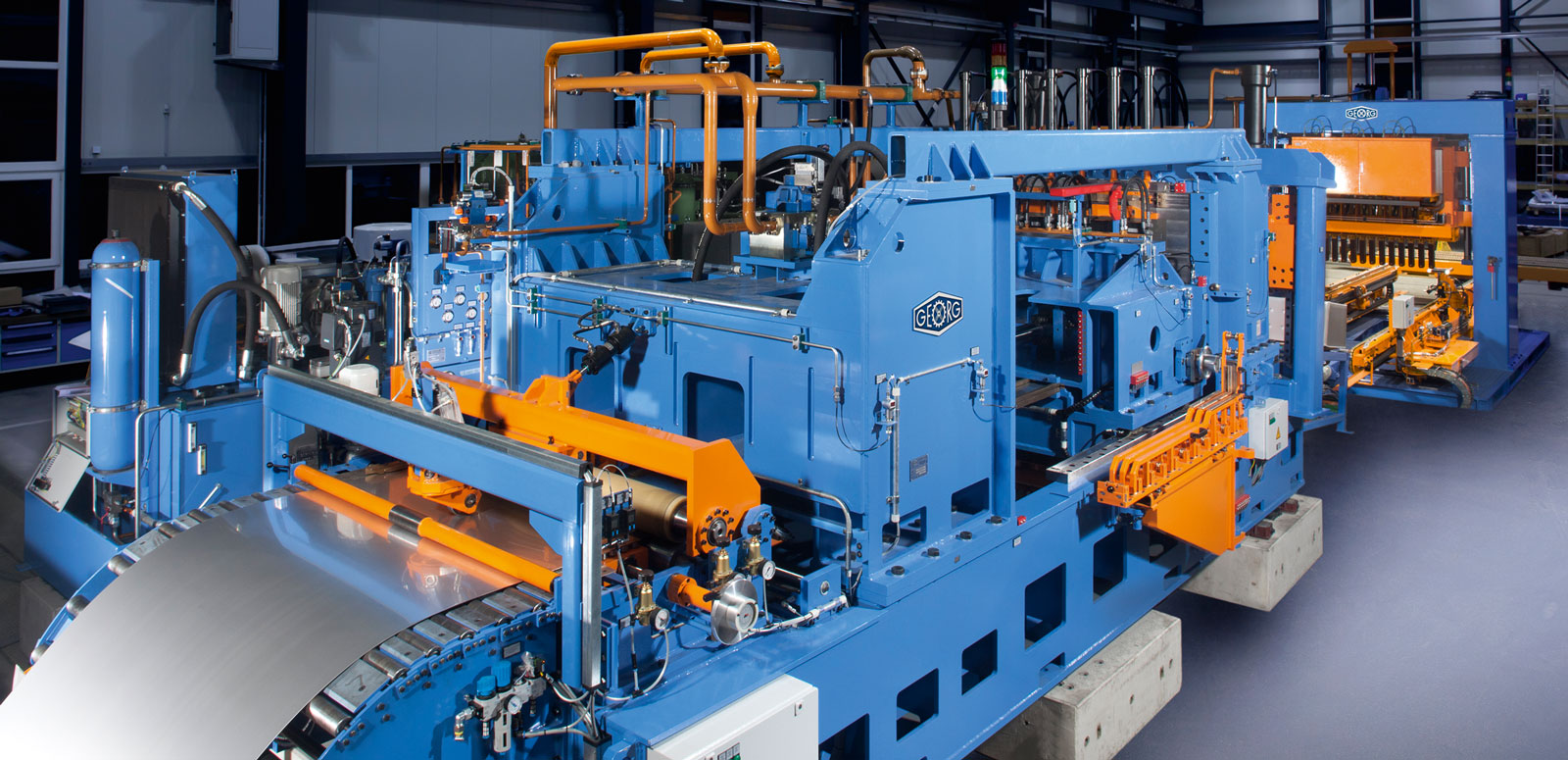

In many plants of ABB in various locations worldwide ABB has been operating GEORG core lamination cutting lines type TBA for decades. Now in recent years ABB has shown its continuous trust in GEORG by ordering a number of core cutting lines from GEORG of different types for various ABB plants in the world. This includes slitting lines for grain oriented electrical steel, core lamination cutting lines for the production of cores of electrical transformers and one ultracorrugation line for the production of corrugated fin walls, which are used at the tanks of distribution transformers to provide sufficient cooling.

Some of the lines have been delivered in the last 2 years and are already successfully in operation in the customers’ plants.

ABB is a major transformer manufacturer throughout the world and offers both liquid-filled and dry-type transformers as well as services for complete life-cycle support, including replacement parts and components.