The evolution of transformer core production

How increasing technical requirements drive the automation of core production

New regulations about low loss transformers in different countries around the world, in line with the greener policies to reduce carbon emissions, have driven important changes in transformer production.

In our case we are referring to the “no-load losses,” also called “core losses,” which are influenced by design, material and process, the latter of which involves man and machine. There is a rapid increase of the market demand for higher-quality and thinner materials.

As these materials require caution in handling, the process of slitting, cutting and stacking of the grain-oriented electrical steel (GOES) is becoming increasingly important, and therefore the equipment in use as well.

Since the material parameters are varying along width and length due to a very delicate process of the steel production, the use of appropriate testing systems to accurately measure the precise losses at each point of the lamination helps to provide more accurate final core losses.

Traditional core production

Manual transformer core assembly implies not only labour-intensive, but also monotonous work with repeated similar movements. Depending on the size, the work can become heavy and difficult. Thus, it is not surprising that motivated and skilled workers are sometimes difficult to find. Furthermore, variations in works results and productivity need to be dealt with.

Advanced core production

Compared to conventional core production, automated core production offers various advantages throughout the process chain.

Slitting process and losses measurements

The slitting process plays an important role as a first step in assuring low losses. Cut-to-length accuracy is dependent on slitting accuracy. With the use of a better-quality material, there is a higher influence of edge burrs that may result from slitting. In addition, the importance of measuring the losses and tracking them on their way to the core assembly, as well as reducing major scrap of material, is also becoming an interesting added value solution to guarantee the final losses and saving precious material, which is generally the major cost of the transformer.

Cut-to-length process and stacking

As the process of cutting and stacking becomes integrated and automated, many advantages become immediately evident:

- avoidance of unnecessary lamination handling, minimum and controlled passages and soft material pick-up systems, avoiding any increase in losses,

- high repeatable stacking accuracy for small air gaps,

- constant monitoring of core geometry,

- increased safety of the automated process.

Especially in “just-in-time” production environments, the reliability of the plant, as therefore its availability for production, becomes an essential point. To ensure this, an anytime, anywhere service solution with integrated preventive maintenance plans, remote access service and control capabilities is needed.

Evolutionary driver in core production – a wide range of products for every challenge

In the past decade, GEORG has delivered over 200 core cutting lines worldwide, of different sizes and levels of automation. To meet the different needs of each customer, the range of these lines include the most advanced and automated equipment, as well as economical solutions – for both large or small manufacturers, power distribution or transformer production. All GEORG production lines are designed without compromising the quality and efficiency, therefore, with a long-term vision.

As process automation is in any case strongly depending on various factors, such as total productivity requirement, batch series, cost of material, the environment and country of installation, with its experience and a wide range of equipment GEORG can propose different solutions to the market, recommending and ensur-ing the best return on investment in each different and particular case.

Automatic cutting and stacking systems

Especially in recent years, GEORG has experienced an increasing automation trend in the transformer core production industry. Automatic systems will always ensure the same high-performance qual-ity level, with much less dependence on personnel availability and worker skills. Automatic assembly systems already in operation at our customers’ sites have shown a reduction in core losses com-pared with manual stacking, greatly reducing the energy consumption for users. Given this trend, GEORG has extended its portfolio of automatic cutting and stacking lines further. There are two essential principles of auto-mated core stacking:

- inline - means the direct connection between cutting and stacking,

- offline - means stacking independent from the cutting process.

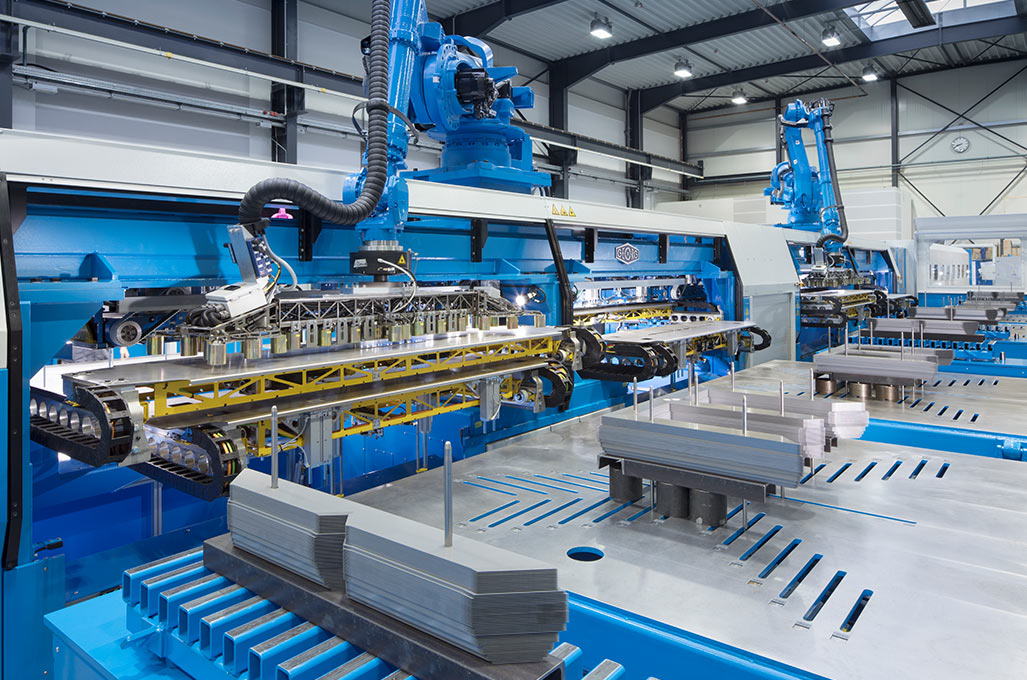

In the distribution sector, the range of automated stacking solutions is mainly dominated by inline systems from the "GEORG precisioncut TBA robotline" se-ries, which use articulated robots for han-dling multiple layers at the same time. The power sector is divided into inline and of-fline solutions.

GEORG robotlines

Over the past years, the GEORG robo-tline has grown to currently four differ-ent machine models. In 2020, GEORG extended the portfolio of highly automated TBA core cutting lines with our standardized GEORG precisioncut TBA300 robotline. GEORG intends to manufacture the first robotic TBA lines without having a prior customer order like in case of the well-known and ex-tremely successful GEORG ecoline con-cept. GEORG’s vision is being able to deliver highly automated TBA core cutting lines out of stock to customers around the world.

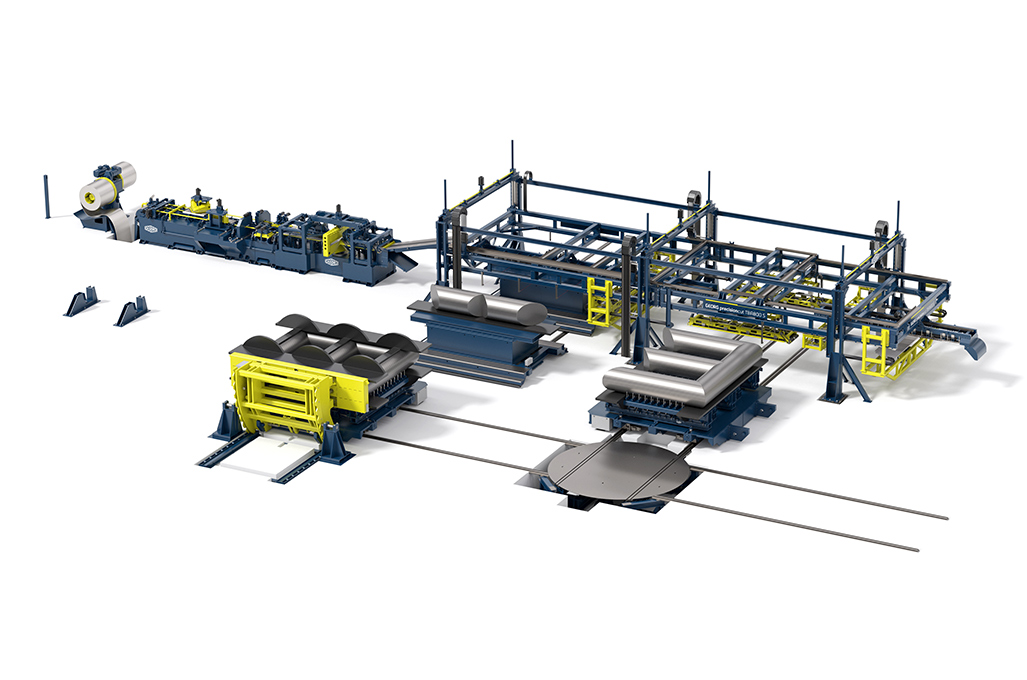

GEORG precisioncut TBA800 S E-stacker

Another important contribution recently added to the portfolio of inline automat-ic transformer core production machines is the GEORG precisioncut TBA800 S E-stacker. This unique machine is designed to auto-matically produce open power transformer cores up to a total weight of 80 tons, with a separated top yoke as well as closed power transformer cores including the top yoke. As the line can be used to either stack such cores (with or without the top yoke) or separate specific leg and yoke logs, it provides a lot of flexibility to fulfil various customer needs at the transformer core service centre.

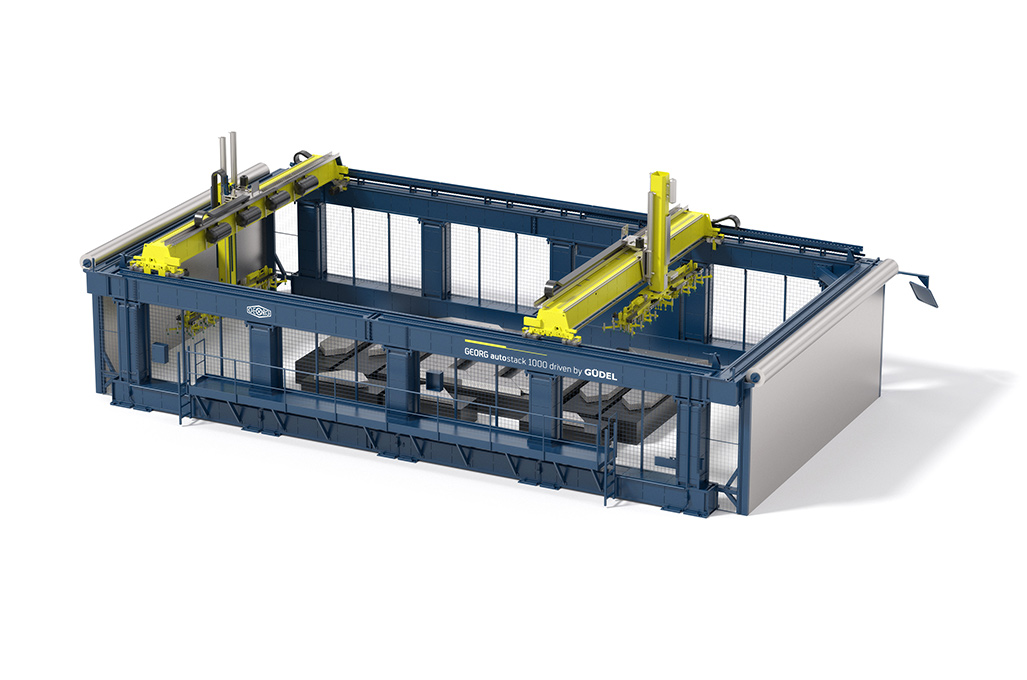

GEORG autostack 1000, driven by Güdel

The portfolio of offline solutions is dominat-ed by the GEORG autostack 1000, driven by Güdel. The machine was jointly developed between GEORG and Güdel Group AG from Switzerland, a company with its excel-lence in automated motion solution in dif-ferent applications. Individually designed, to be integrated into the customer’s production surrounding and considering available space and existing equipment such as core stacking tables, the GEORG autostack 1000 can automatically stack power transformers of up to 300 tons and five limbs with a total yoke length of up to 9 m.

GEORG protectionworld

The GEORG protectionworld Life Cycle Quality Management offers GEORG cus-tomers worldwide an all-round carefree package for the entire life cycle of their machine or line. The customers can con-centrate on their core business. The dif-ferent service solutions help them signifi-cantly to lower the operation cost of their line and increase their profit. In addition to a well-trained service team, GEORG also uses automated service solu-tions that benefit both sides.

Experience. Innovation. Reliability. Profitability

With its vast experience as well as its broadly positioned conventional and automated products for the power and distribution market, GEORG combines nnovative technological competence with high economic efficiency. From planning, development and im-plementation to logistics and service, GEORG uses both standardized and in-dividually tailored products and services that combine classic mechanical engi-neering with state-of-the-art digitaliza-tion. Customers receive decisive compet-itive advantages, a reliable partner and a high level of process reliability. With its in-house innovation department and selected technology partners, GEORG will continue to drive evolution of trans-former core production in the future.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/experience/2023/12/Vollautomatische_Putzeinrichtung/georg-experience-vollautomatische-rm_kachel.jpg)