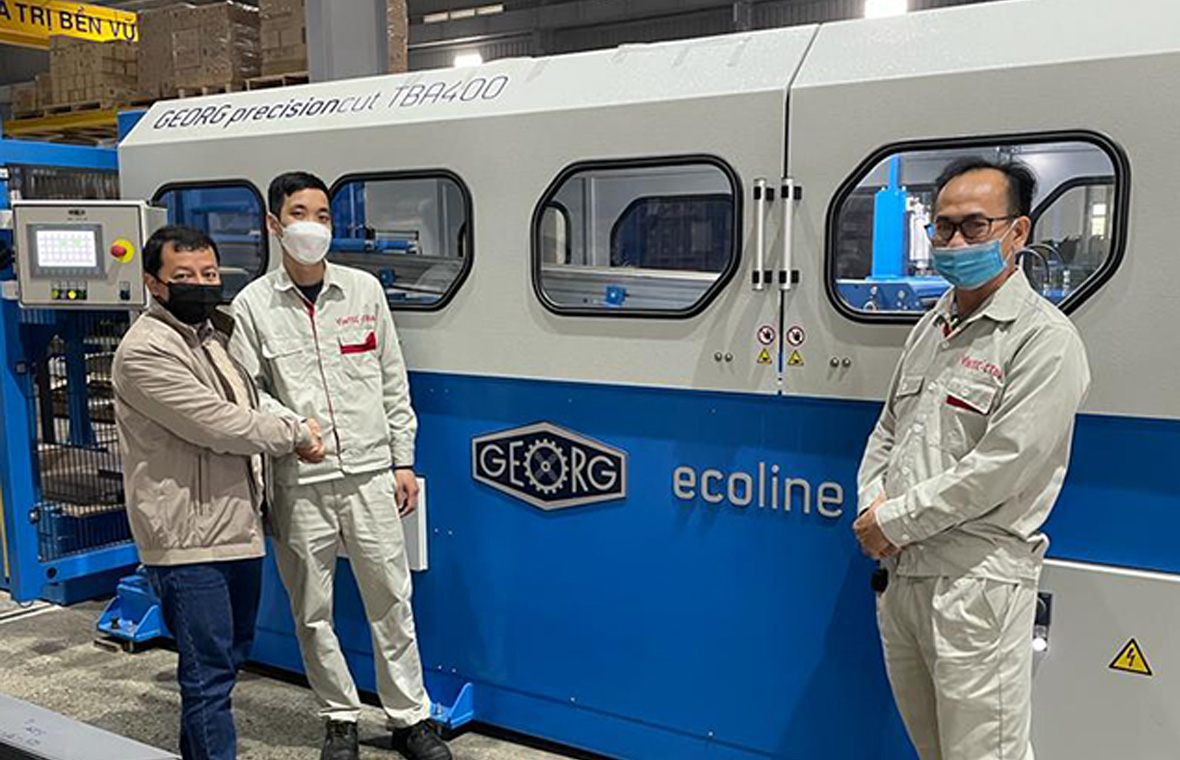

Remote Service in Vietnam

Travel restrictions during the pandemic made it often impossible to visit our customers on site. This also applied to the installation and commissioning of our machines. However, we successfully supported our customers remotely, through our online service.

In Vietnam, we installed two TBA400 eco lines with our Vietnamese representatives and online support from Heinrich GEORG Germany. Our customers are very satisfied with their new machines.

Mr. Thong - Production and Technology Head at Vintec

„Vintec is a newly established and family owned company with 60 employees operating since 2019. Regarding our company size, investing in a GEORG machine is a very big step. Regardless of the big investment, the technology and durability of the GEORG solution has been so impressive that our management thankfully decided to buy a GEORG cutting machine. That investment improved our production quality and productivity almost instantly.

After putting the ecoline into operation in July 2021, we are having to apply the ratio: 1 cutting day - 3 days stacking, to keep up with the cutting capacity of the machine. The core of transformer products cut by the ecoline has a measured loss of 5-12% lower than before.“

Mr. Pham Dang - Production Director at HBT

"We are completely satisfied with GEORG's ecoline cutting machine. It runs quietly and reliably. We have cut over 1.2 million cuts and the burr height are still within satisfaction. Before GEORG‘s ecoline, we could only produce at most 100-120 distribution transformers per month, on average. Last year when we put the ecoline into operation, we produced 300 units per month on average and we set a production target of 600 units /month in 2022."

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/experience/2024/05/GEORG_AISTECH_2024_experience.jpg)