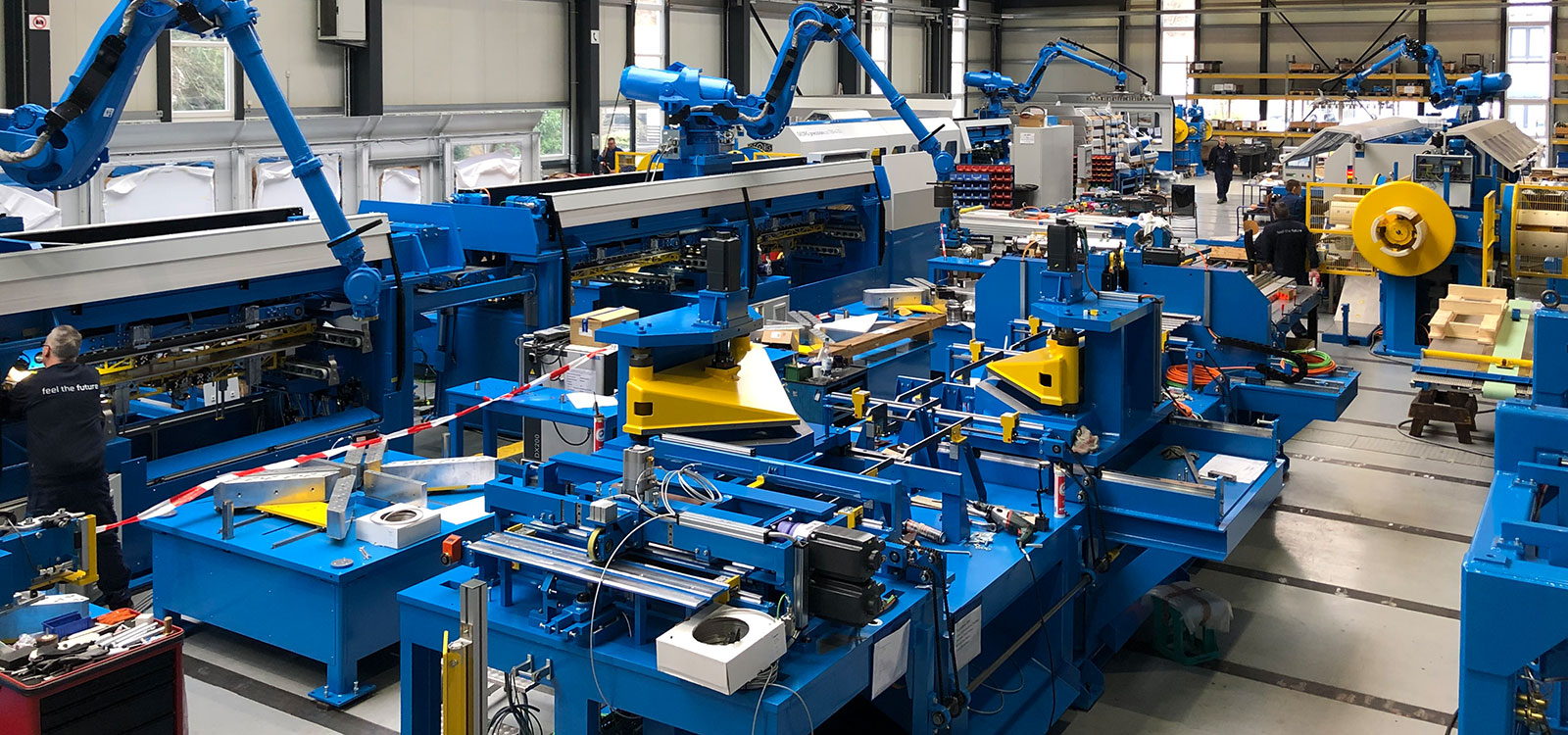

Newly developed GEORG precisioncut TBA 400 robotline

GEORG is proud to present its newly developed GEORG precisioncut TBA400 robotline. With this state-of-the-art Step Lap Lamination Cutting Line including fully automatic stacking feature GEORG provides an impressive proof of its readiness to tap the potentials of digitalization and smart manufactoring.

The GEORG robotline allows the automatic cutting and stacking of up to eight complete (closed) or open transformer cores simultaneously at a minimum manual workforce

and is available in various levels of output – from basic version up to high speed configuration.

Features like the GEORG core editor aim for highest degree of automation in transformer core production and various logistic concepts support the downstream core handling process using for example driverless vehicles.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/experience/2023/12/Vollautomatische_Putzeinrichtung/georg-experience-vollautomatische-rm_kachel.jpg)