Manufacturing management via specially developed dashboard

Increasing pressure on costs and shorter production times – GEORG launches an efficiency booster for its customers' manufacturing.

Only two years ago GEORG founded an order independent Innovation Department mainly focussing on the development of digital solutions for its customers.

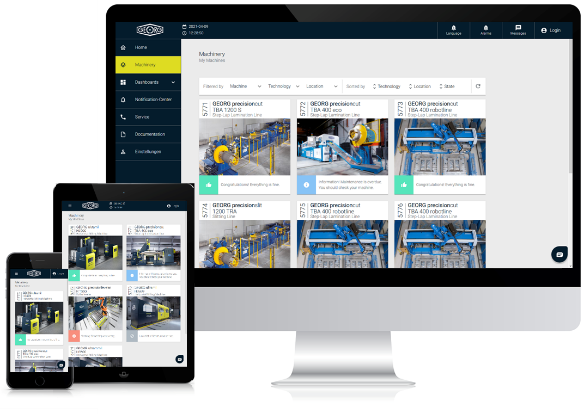

One of the latest developments is the GEORGdashboard. It has been developed to make the customers‘ manufacturing management easier, faster and more efficient. The dashboard enables the collection, storage and analysis of production data, machine operation conditions, status and operation parameters. At any time and from anywhere you get an actual overview on the essential key values and the machine or line condition for a better control of your production flow.

The key advantages of the GEORGdashboard:

- Quick overview about the current status of all machines

- Increase of efficiency and reduction of downtime

- Analysis and improvement of key performance indicators (KPIs) and machine conditions

- Advice on how to improve machine performance

In future the GEORGdashboard will also serve to digitize manual processes or part of processes easily and without additional hardware.

Make your production more efficient, more transparent and cost-effective.

The GEORGdashboard is available for all new GEORG machines and lines as well as for machines from other manufacturers. It can be applied to a single machine as well as to complete production chains. Retrofitting of existing plants is also possible.

In times of increasing pressure on costs and shorter production times digitalization can be one of the best efficiency drivers. Digital transparency offered by the GEORGdashboard will increase safe planning and productivity. Processes can be designed more efficient and consequently costs reduced to ensure further growth, competitiveness and continuity of a company.

Interested?

Further information available here:

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/experience/2023/12/Vollautomatische_Putzeinrichtung/georg-experience-vollautomatische-rm_kachel.jpg)