Invests in own mechanical production

GEORG orders another REIDEN 5-axis machining centre

GEORG continuously invests in mechanical production

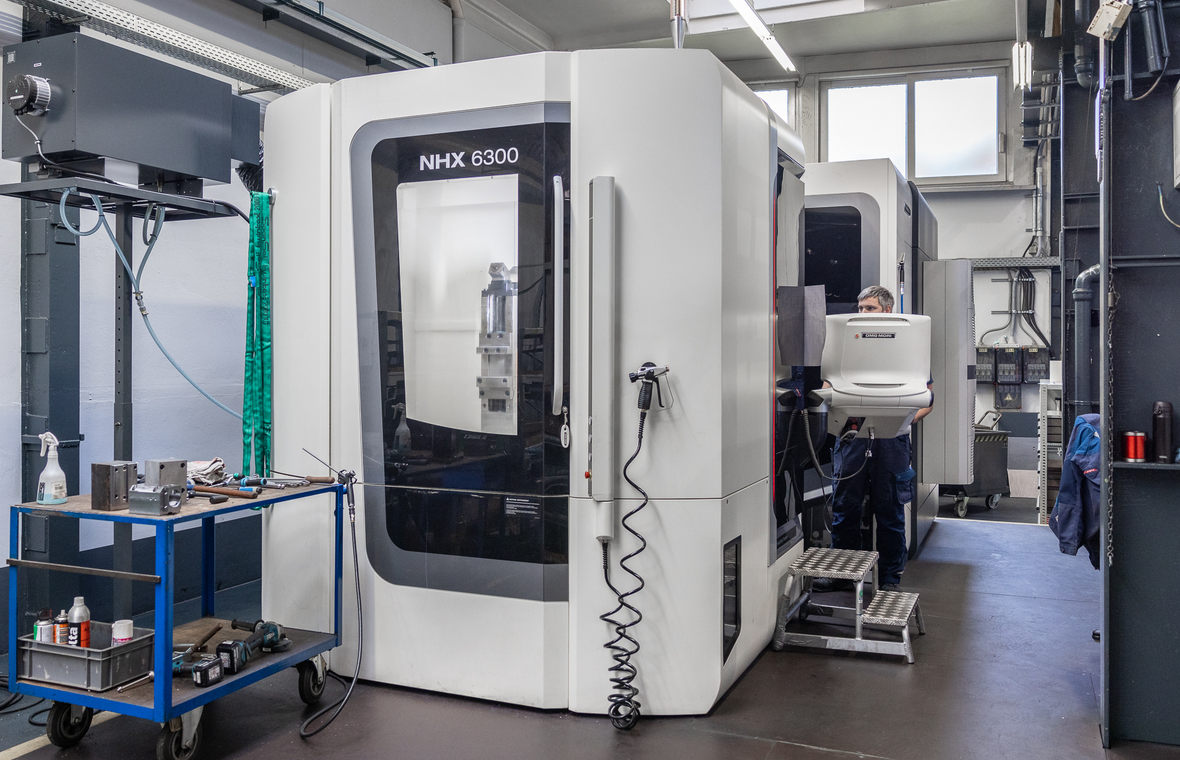

Heinrich GEORG Maschinenfabrik GmbH continues to regularly renew the machinery of its own mechanical production. After commissioning the first REIDEN machine in 2020, GEORG is now already investing in a second machine from the Swiss machine tool manufacturer.

The REIDEN RX12 is a compact 5-axis machining centre with a very small footprint. The machine can machine workpieces with dimensions of 1.300 x 1.450 x 1.000 mm completely in one set-up with highest accuracies. Despite its compact appearance, the machining space is enormous compared to the machine size.

According to Dr.-Ing. Wieland Klein (Chief Technical Officer and member of the board at GEORG), the investment in another REIDEN was the logical continuation of the manufacturing strategy at GEORG. "As a manufacturer of high-precision machine tools and strip processing lines, GEORG cannot compromise on the selection of machine tools in our own production. That's why we only invest in machines from first-class suppliers to be able to guarantee the necessary quality and precision."

In addition to the REIDEN machines, several machines from DMG-MORI and Mazak, a Scharmann Ecoforce machining centre, a WEILER lathe and a portal type Stöckel surface grinding machine have been purchased in the recent past.

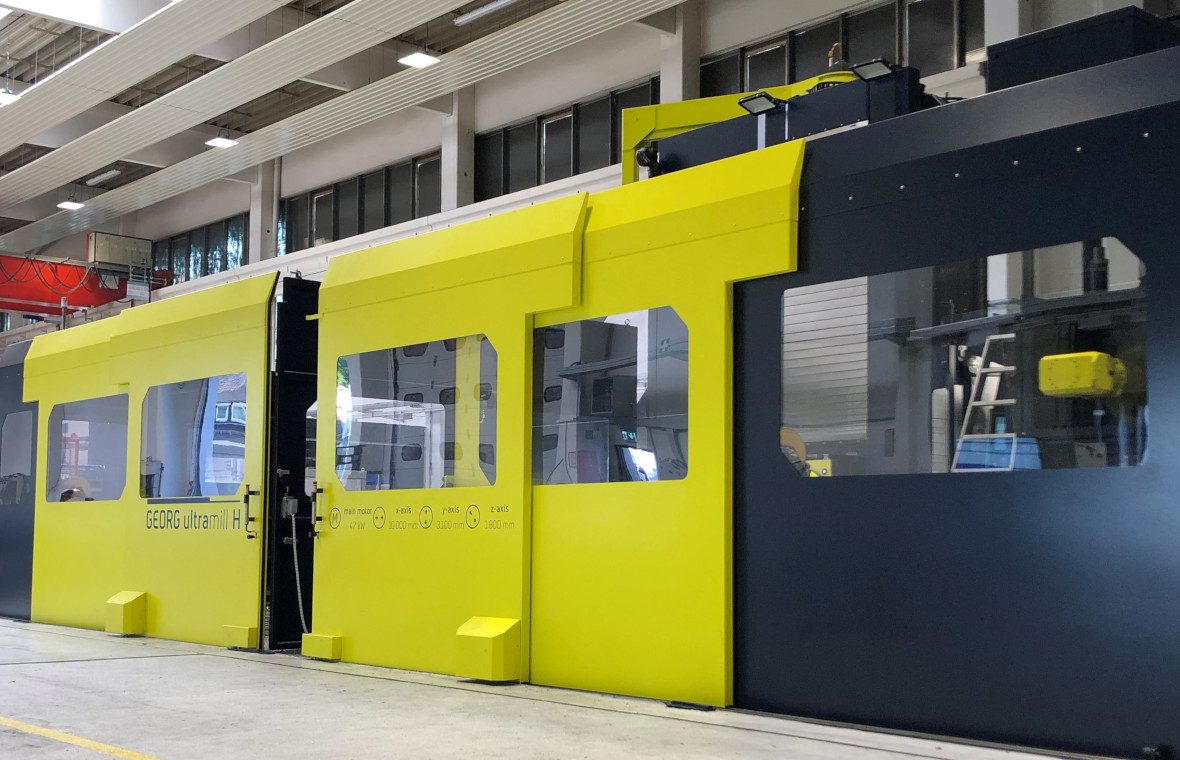

In addition, two years ago GEORG commissioned the first travelling column milling machine of the type GEORG ultramill 3000. The machine is an in-house development of the GEORG machine tool business unit and complements the machine park in the large parts production.

"With our machinery, we can produce components with a total weight of up to 25 tons with highest manufacturing tolerances. We make no concessions when it comes to the quality of our components, which is why we have a very high vertical range of manufacture. Almost 100% of the parts that we do not manufacture ourselves are sourced from domestic companies." says Dr. Klein.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/experience/2023/12/Vollautomatische_Putzeinrichtung/georg-experience-vollautomatische-rm_kachel.jpg)