IMPOL relies on GEORG modernisation

Heinrich GEORG GmbH: GEORG modernises Knövenagel scalper at IMPOL Seval

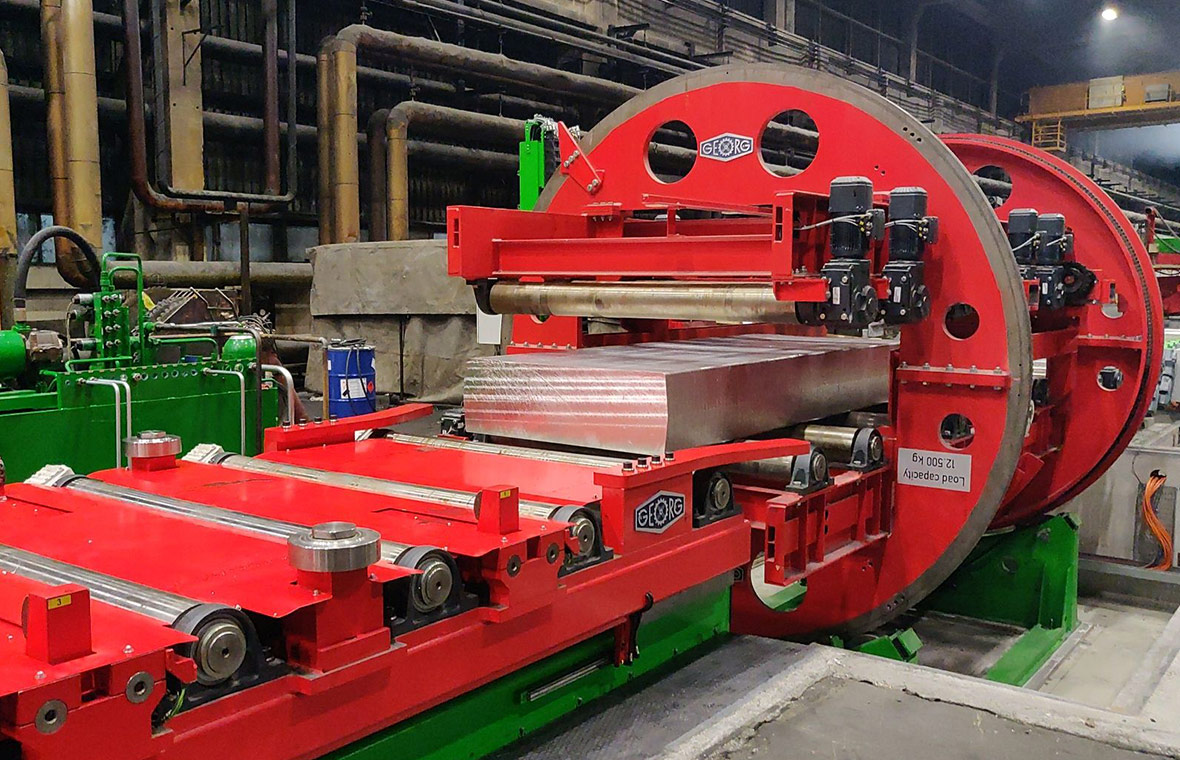

The Serbian plant in Sevojino, which has been part of the Slovenian IMPOL Group since 2002, commissioned Heinrich Georg GmbH to modernise an almost 50-year-old ingot milling machine. The scope of supply includes both a completely new bed table group including the machining table with automatic block clamping device and a new turning device with the associated loading and unloading roller conveyors. IMPOL maintenance chief engineer Vladimir Andric sums up: "Thanks to the new equipment, we can meet our customers' requirements faster and better. All in all, it is a reliable system that saves us time and money. We were also able to increase our capacity as planned."

The background to the modernisation at IMPOL was a necessary increase in capacity of the almost 50-year-old plant due to larger slab dimensions. According to Jan Ebener, Head of Sales Machine Tools at GEORG, modernisations of third-party machines are part of the normal service business, which GEORG bundled last year into a central division that is on a par with the new machine business. "However, such a machine must still have a certain technical basis so that it makes sense for us. When we offer modernizations as a new machine manufacturer, our customers expect the same, very high-quality standards from us that we demand from our new machines."

During the installation and commissioning of the equipment, it was important to keep the downtime as short as possible so that the machine could go back into operation on time after the rebuild phase. Only through intensive dialogue between IMPOL and GEORG it was possible to keep to the customised schedule. Overall, the maximum possible workpiece weight was increased by 50% as a result of the modernisation measures.

IMPOL is one of the largest aluminium producers in Europe and manufactures aluminium products for the world market in its plants in Croatia, Slovenia and Serbia for the automotive and pharmaceutical industries, the construction and transport sectors and the aerospace industry, among others.

"With about 600 employees, we currently achieve an annual capacity of about 120,000 tonnes here in Sevojino. " reports Jelena Matic, Foundry Manager at IMPOL Seval. "From the very beginning, GEORG, as one of the leading manufacturers of large machine tools, supported us optimally in the entire project. We are completely satisfied not only with the new equipment itself, but also with the integration into the existing plant, as well as with the service. Even during the peak phase of the pandemic, the GEORG technicians and project managers did everything they could to get the equipment up and running on time, so that we were able to achieve the planned production capacity after only a very short ramp-up phase," says Jelena Matic.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/experience/2024/05/GEORG_AISTECH_2024_experience.jpg)