High automatic stacking of distribution transformer cores – Ground for smart manufacturing

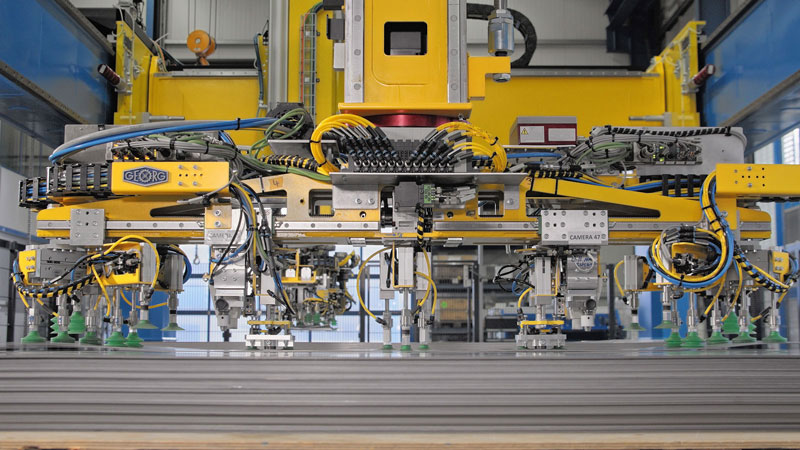

The newly developed GEORG autostack 400 is an offline system for the automatic stacking of distribution transformer cores, developed within the cooperation between GEORG and GÜDEL.

This highly automated system is equipped with an interface to GEORG core cutting lines and an integrated data management for core production. The direct data transfer from the cutting line to the robot unit makes time-consuming manual processes redundant.

By this data coupling, the new systems can be easily integrated into digitally networked environments and thus prepare the ground for industry 4.0 / IoT.

GEORG and GÜDEL are looking forward to continue their cooperation in the field of automatic core stacking by developing autostack systems for medium and large power transformers.

Product Portfolio:

autostack 400

- Lamination width: 70 to 440 mm+

- Lamination length (center line): up to 1750 mm

- Stack height: max. 440 mm

- Gantry type: fixed

autostack 600

- Lamination width: 70 to 640 mm

- Lamination length (center line): up to 3500 mm

- Stack height: max. 640 mm

- Gantry type: fixed / movable

autostack 1000

- Lamination width: 100 to 1020 mm

- Lamination length (center line): up to 5000 mm

- Stack height: max. 1600 mm

- Gantry type: fixed / movable

- Core design: 2, 3, 4, and 5 leg cores (depending on type)

Features:

- Processing of complete and half logs

- Production of flat yokes

- All types of step lap

- Utilization of existing core stacking tables

- Interface to GEORG core cutting lines

- Data management for core production

Advantages:

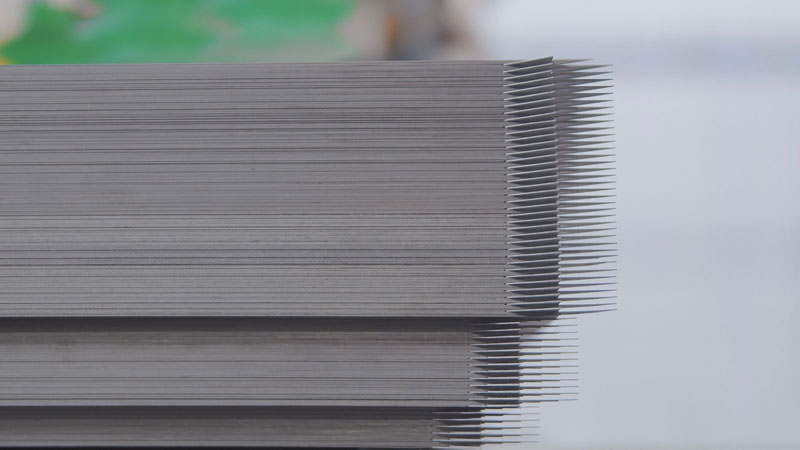

- High accurate stacking

- 100% repeatable stacking quality

- Adjustable gaps

- Reduced mechanical stress

- Reduced transformer losses

- Labour cost savings

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/experience/2023/12/Vollautomatische_Putzeinrichtung/georg-experience-vollautomatische-rm_kachel.jpg)