GEORG converts strip line at Hulamin 100% remote to Combiline

The conversion of the cut-to-length line No. 5 to a "Combiline" of the South African customer Hulamin was carried out completely by digital tools during the Corona pandemic. It went successfully into operation exactly on time and within budget. At Humalin, the remote rebuild realized by the GEORG specialists is now the "talk of the company".

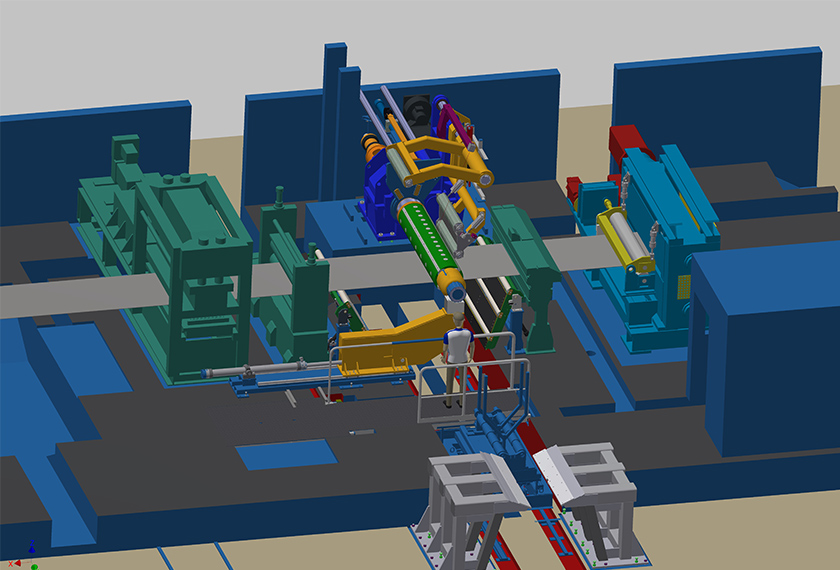

Due to high capacity utilization at the Hulamin mill in Pietermaritzburg, South Africa, the management decided to convert the cut-to-length line 5, which Georg had commissioned in 1999, into a "Combiline" capable of either slitting or trimming and coiling strip.

It was planned to integrate a new recoiler with a pressure arm, support bearings and a coil lifting car for the removal of coils with outside diameters of up to 2,200 mm and up to 15 t weight.

Hulamin had placed the order with GEORG at the end of 2019. At that time, both partners could not have known that the rebuild would fall into the third wave of the Corona pandemic. By April 2020, the federal government had imposed a travel ban, and by December 2020, it was clear that the project would either have to be postponed indefinitely or the rebuild and commissioning would have to be completed without GEORG personnel on site.

The travel restriction and the long distance between the locations were not the only obstacles. The problem was additionally aggravated by the situation that during the pandemic about 50 percent of both companies’ personnel was working from home.

Both partners jointly decided to implement the project to the greatest possible extent remotely from Georg’s headquarters in Kreuztal, Germany. The basis for the communication between the process control system of the upgraded line and the specialists at the Georg head office in Germany was and still is the Georg Connected Service platform.

Quick access to the machine control system and the plant components is assured by a dedicated online-support software. Data is exchanged exclusively via direct VPN connection, which has become a proven and reliable standard among an increasingly growing number of plant operators.

The project team used virtual reality to work directly on the plant: employees on site wore helmets with cameras mounted to them so that others could get an impression of the current situation even from a distance. Additional information was fed in via AR glasses, so employees in Germany had a "live" view of the plant in certain situations.

During the conversion phase, an extensive project meeting was held every week with Microsoft Teams®. Every day, there was an online meeting in a smaller circle to discuss the current activities, which was also attended by the external engineers from GEORG on site.

Consequently, the final acceptance tests went extremely smoothly. On April 30, 2021, precisely on the originally scheduled date, the project team handed over the multi-purpose line to Hulamin’s production team. Ever since that day Hulamin has been using the line on a three-shift basis - one shift per day as a cut-to-length machine and two shifts per day as a side-trimming and recoiling line.

The used digital tools have proved highly successful in the installation phase of the equipment and during the integration and connection of the electrical, hydraulic and process control systems.

Hulamin's management considers the project an outstanding success: the supposedly unachievable has been achieved. The successful rebuild was and is the "talk of the company".

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/experience/2024/05/GEORG_AISTECH_2024_experience.jpg)