Demand-driven core production

From manual to fully automated

The evolution of core assembly from manual stacking to fully automated production received much coverage in recent times. Besides these two essential techniques, there is a middle course as well. Here, the cutting lines produce ready stacked limbs and yokes (jointly called “logs”). The assembly of the actual core is performed by taking the legs as they are and by inserting yoke laminations.

This method, which already reduces the dependency on manual work considerably, is especially suitable for production in larger lots or when windings shall be wound directly on the legs. It is a perfect environment for high output cutting of the core laminations. In addition, there is the necessity for smooth and ergonomic execution of the remaining manual work, which makes great demands on the equipment.

Core manufacturing process with a GEORG precisioncut TBA400 and core assembly tables

This article is about the automatic Step-Lap Cutting Line GEORG precisioncut TBA400 in high-speed configuration, which is also used by Czech transformer manufacturer Elpro-Energo Transformers s.r.o. This machine is designed for the highest output values using advanced punching and cutting parts combined with a bottom-pin log stacking system, which is considered one of the most efficient ways of distribution transformer core production.

Set-up of the GEORG precisioncut TBA400

The first part consists of a decoiler, on which coils of electrical steel of a required width are loaded and uncoiled during operation. The great advantage of having multi-mandrel decoiler systems is the possibility of changing coils by the operators while other coils are being unwound and cut at the same time.

GEORG offers a wide range of different systems with various automation options. From manual in-feeding up to automatic strip in-feeding and realizing strip change times of less than a half-minute greatly reducing the machine’s non-productive times. The punching and cutting part of the GEORG precisioncut TBA400 is the heart of the machine being equipped with a wide range of tools. The key for the highest output values is the idea of applying CNC controlled longitudinal movement to all punching and cutting tools to synchronize punching and shearing events, hence minimizing the number of stops in the strip movement.

A belt conveyor transports the cut laminations over to the bottom-pin log stacking system. An arrangement of pins located on stacking cars ensures the perfect alignment of the finished stacks. The laminations are transported above the designated positions, being dropped right through the punched holes for the pins, sliding down in alignment with the rest of the stack. The stack gradually grows until it forms a complete limb or yoke.

The GEORG precisioncut TBA400 is equipped with motorized stacking cars providing enough space to stack several logs in the transverse direction. The motorized movement also allows batch production, thus achieving precise positioning for different transverse stacking positions. In order to achieve a maximum cutting performance and minimize the movement of the stacker, it is best if a full sequence (one magnetic circuit) fits in one row on the stacker.

For medium lengths of laminations of less than 650 mm, 10 stacking spaces can be created in one row, so two full cutting sequences (two identical magnetic circuits) can fit there, which results in even higher performance, as to the laminations of medium length up to 1200 mm, five stacking spaces can fit in one row. Laminations of medium length up to 2200 mm or 2500 mm have three or two stacking spaces available, which already requires a different cutting sequence.

The GEORG precisioncut TBA400 uses two stacking cars which can both be swapped automatically. On one of them, stacking procedure can take place, while from the other, ready cut cores are being taken away, or positions of the alignment pins are being changed for the following designs.

Measurement of packet height plays an important part in the stacking process. It is needed to compensate for the actual sheet thickness, as some deviations from the theoretical values are required.

Assembling of transformer cores

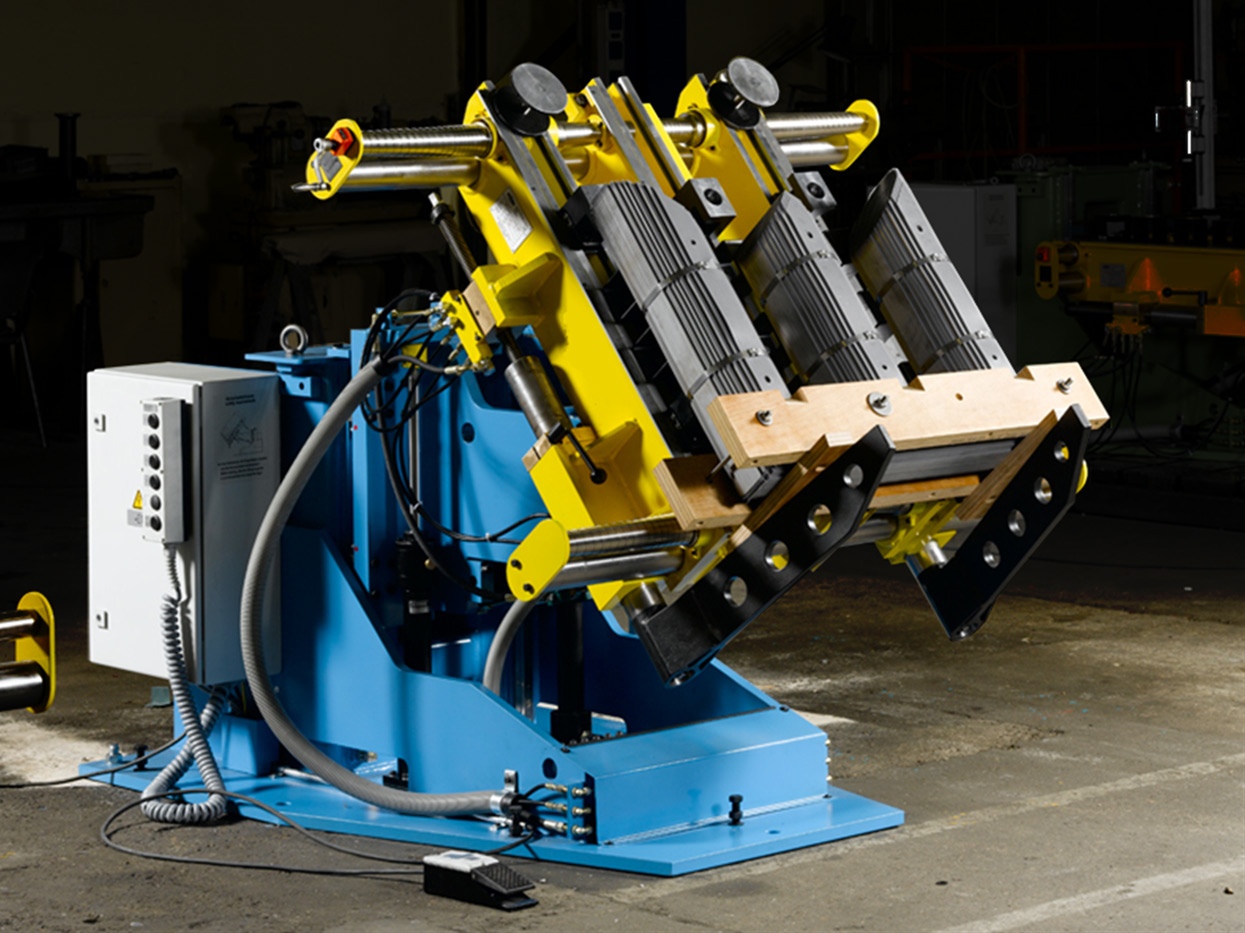

Building a magnetic circuit by means of lower yoke insertion can be done in two different ways - in a vertical or horizontal position. There may be limitations for horizontal assembly due to yoke cross-sections and yoke clamp shapes, in which cases the vertical assembly will be preferred. In both processes, the magnetic circuit is built without an upper yoke, and the magnetic circuit is then E-shaped. The upper yoke is inserted only after all high voltage and low voltage coils have been put onto the limbs.

The whole process of building starts already on the stacker, where laminations are already grouped into limbs and yokes. The alignment pins are replaced by others, more suitable for the transfer of whole limbs which have a fixed shape. The limbs are removed by crane. After fixing all limbs by means of aligning pins to the assembly table and mounting the necessary accessory like stands for aligning pins, supports and lever clamps, which are necessary so that the limbs remain in a completely steady position. For vertical building, the table is tilted by 90° towards the ground by means of a traverse and the lower yoke, now shown to the top, begins to be built by individual packets.

After completing the yoke assembly, the table is returned to the horizontal position and then rotated by 180° so that it can be tilted along with the finished yoke towards the ground, and the core can be removed by a crane with straps.

As for the horizontal assembly, the lower yoke is built in the same way as in the vertical assembly, only in the horizontal position because the table tilts straight down with the finished yoke.

The assembly tops of all tables are easily height adjustable by the operators to compensate for different body heights and also the stacking heights, which rise during the process.

For the demand of low losses and high quality of the transformer, the accuracy of both, the cutting of the laminations as well as the stacking of the laminations to the core with the lowest gaps in the corner joints between leg and limb sheets are essential. With the GEORG core lamination cutting lines TBA and the GEORG stacking tables, all this can be achieved.

Black. White. Or between.

The range of worldwide leading GEORG TBA cutting lines is available for high level and medium requirements for power and distribution transformers. According to application range and needs, various types are available and can be tailored to the individual customer requirements.

The cutting lines can be completed by classic or highly automized stacking systems. E.g., the GEORG robotline offers an integrated fully automatic cutting and stacking solution for distribution transformers without any manual stacking. The GEORG autostack represents a highly automized unmanned stacking solution offline. And the GEORG precisioncut TBA400 uses two stacking cars which can both be swapped automatically. This machine is designed for the highest output values using advanced punching and cutting parts combined with a bottom-pin log stacking system, which is considered one of the most efficient ways of distribution transformer core production.

Interview with René Mrajca

CEO of Elpro-Energo Transformers s.r.o.

Could you briefly introduce your company?

It was a direct route from trading transformers to actual production. I studied high voltage engineering at the University of Brno. In my first job, we started selling SGB transformers from Regensburg and later Neumark. I have been selling transformers all my life until I got the idea to make them by myself.

What made you decide to start your own transformer production?

Our requirements grew, and we could not find a partner on the market who could meet them, especially in terms of quantity, deadlines and finally, quality. And so, we had no choice but to make our own arrangements.

With what background and professional experience did you make your decision to build a new transformer plant in Europe?

If you spend your whole life with these things and visit different manufacturers, you develop a relationship with these products. You know what the customer wants, what they are looking for. These things are obvious to you. In school, you learn the basics and the rest in daily practice.

To what did you pay particular attention to when setting up the new plant?

We built the administration building and the first hall. Now we are about to finish the second. We have set ourselves clear goals for the construction, such as avoiding metal elements such as sheet metal on the facade of the hall in order to avoid a Faraday cage. The main material we used was wood. We wanted to let in as much natural light as possible, which we solved with dome-shaped skylights, and we integrated the heating into the floor - for the entire 6500 m2. We have our own kitchen and cook with fresh food.

We can imagine that the set-up of a new factory is challenging. What did you find most helpful?

The most important thing is always the enthusiasm of the people for the task. When a bunch of enthusiastic people come together and put their heart and soul into their work, eventually all problems are overcome, and the work is blessed. It is a pleasure to live and work in such a team.

Why did you choose GEORG machines?

GEORG was the obvious choice. GEORG is a legend in the transformer industry. Any quality company with a name runs a GEORG. We just picked the right type of machine.

What is your experience in handling the project? How do you rate the cooperation with GEORG?

GEORG people are professionals who know their job, and the installation went smoothly. Everything with great precision, often even with laser precision. They know exactly what to look at so that there are no problems later in operation. And if there are any, there is a hotline where the problem is solved immediately. We often reach out to their experience when there is a problem.

In addition to a good machine, support from the supplier in the event of problems is increasingly important. The GEORG TBA line is equipped with the GEORG connected service system for online support. How is your experience with it?

This service works great. It is perfect that there is always someone on the other side who understands the machine and can advise. We have solved problems with their help on several occasions. The worst thing is when the customer is waiting, and your machine is down due to a malfunction.

You have decided in favour of both the GEORG core cutting lines and various core assembly tables from GEORG. What is your experience with these?

We also bought all the tables from GEORG because they fit perfectly with the design we produce. It is not easy to build a table that can support or manipulate one ton or three tons or even more and which must be accurate to the tenth of a millimetre. Inaccuracies affect the resulting core loss.

When making your selection for the core cutting line, you opted for a line for the production of complete limbs and yokes and the subsequent manual core production - not for a robotic solution. Why?

We felt that robotization was only in the early stages of development when we bought the equipment back in 2018. We were limited by its size also by the size of the cores the robot could stack at the time. But everything has an evolution. We went with the option of manual work for core assembly.

Does reducing losses play a major role?

The strict Ecodesign Tier 2 standard has triggered a demand for transformer sheets that the market was not at all prepared for. It affects the steel industry and the rolling mills. However, nobody has invested in this industry for a long time because its future in Europe is unclear. Most of these materials were imported from Asia. Today the world is changing, and transportation is expensive and complicated. Deliveries from Asia are delayed. So, we are waiting for investors who

will decide on new investments and modernization. A single premium grade quality producer for the whole of Europe is not sufficient. This quality is not on the market, and it affects all transformer manufacturers.

Who are your customers? Where are your main markets?

The most important markets are the Czech Republic, Poland, Germany, Austria and Slovakia. Simply in our neighbourhood so that everyone could visit us at any time. Everyone was able to get an idea of our production status and receive their product personally.

Do you have any special features (unique selling points) with your transformers that you particularly emphasize?

It is too early today to rate any highlights. We have designed the transformer ourselves, including its electrical and mechanical construction. Our slogan “Trafo, které Vás přežije” that means “the transformer that will outlive you” is what we demand of ourselves. Now, all we need is the last step, which is low-frequency filling. In this way, the product is ready and ready to be delivered to the customer. For us, it is a service to people that they can have light or heat in their homes.

Company Information

Elpro-Energo Transformers s.r.o.

Address: Hnojnik 472,

CZ-739 53 Hnojnik

Homepage: www.czechtrafo.cz

Founded: 8 October 2018

Production area: 2 x 6500 m2

Number of employees: > 50 employees

Product range: 25 kVA to 10 MVA

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/experience/2023/12/Vollautomatische_Putzeinrichtung/georg-experience-vollautomatische-rm_kachel.jpg)