Highest Efficiency throughout the entire Core Building Process

The partnership between GEORG and GÜDEL now lasts for more than five years. During that time, both family-owned companies used their combined experience to develop automated solutions in transformer core assembly.

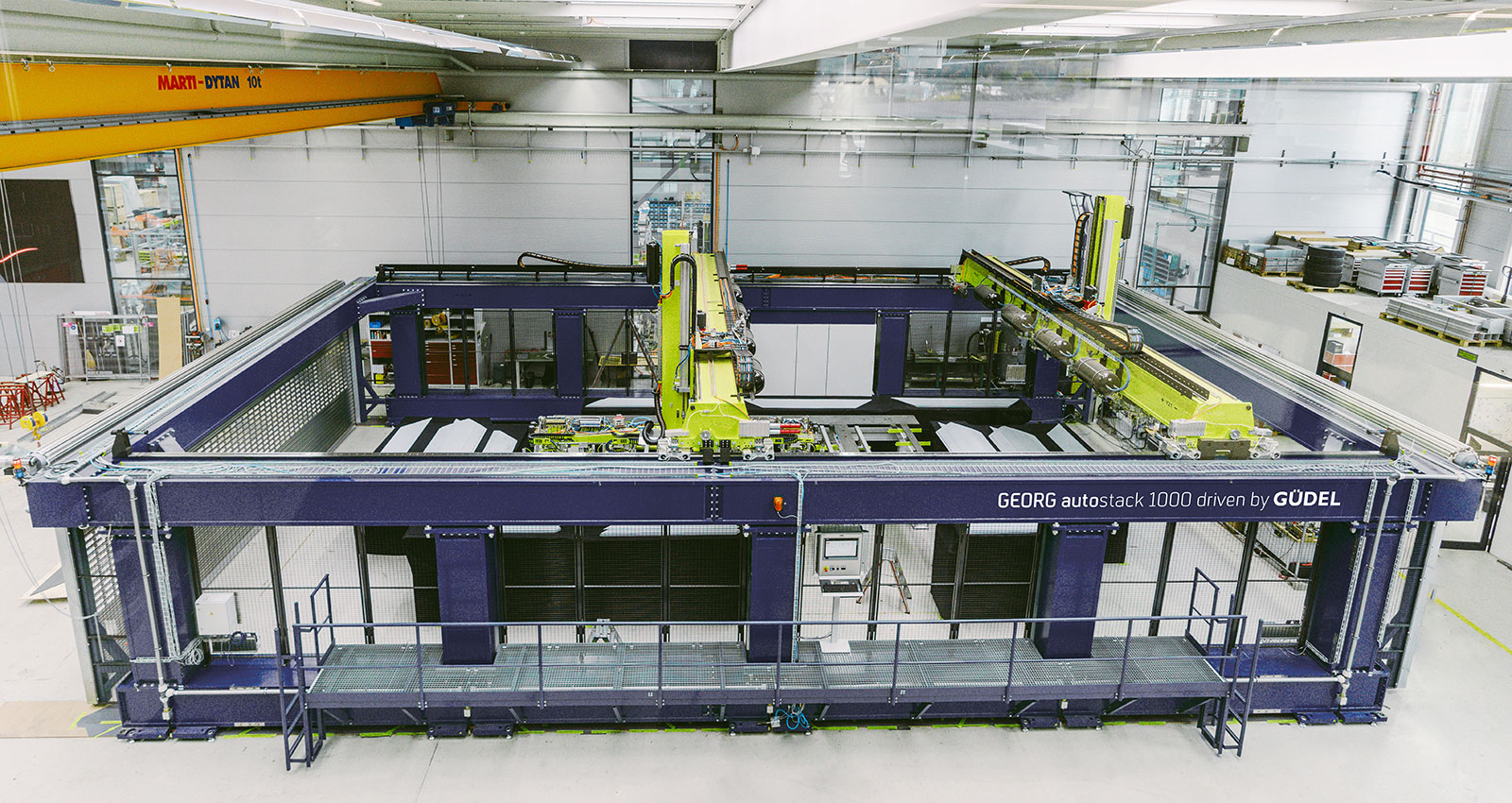

On the large end of the scale the GEORG autostack 1000, driven by GÜDEL can automatically stack large power transformer with yoke dimensions of up to 10 m. The core designs can be diverse, with different kinds of step-lap, split legs and divided yokes.

The GEORG autostack 1000 can deal with all these different requirements and ensures consistent stacking results.

In combination with a GEORG precisioncut TBA1000 S the entire core building process can be realized in one procedure. No large intermediate storages are required and the material can be transferred direcly to the autostack system after cutting.

The GEORG autostack 1000 is connected to the TBA line via the integrated data-management system. Therefore, an integration in the digital network of the production plant can be easily realized.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/experience/2023/12/Vollautomatische_Putzeinrichtung/georg-experience-vollautomatische-rm_kachel.jpg)