Technology

High Productivity in Electrical Steel

Solutions for a sustainable supply chain

Our products for electrical steel

Roll grinding machines

- GEORG ultragrind 10

- GEORG ultragrind 25

Coil processing NGO

- GEORG precisionslit TRA

- GEORG precisionpack

- GEORG inspectionlines

Coil processing GO

- GEORG precisioncut TBA

- GEORG precisionslit TRA

- GEORG ultracorrugation

Your Benefit

- High Productivity

- Short Set-up Time

- Low Man-power

- Low Maintenance

- High Energy Efficiency

- High Work Safety

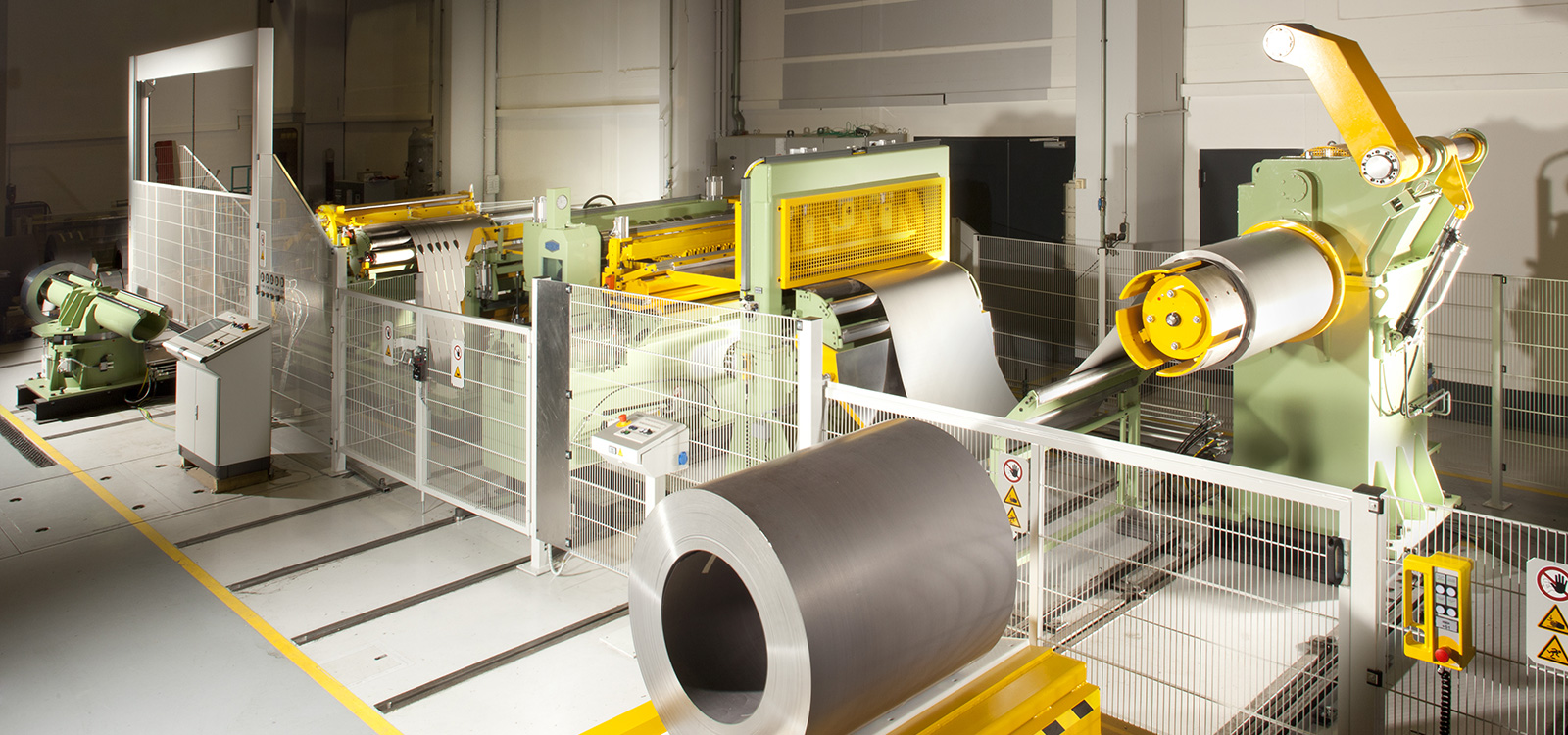

From flat rolled coil to lamination

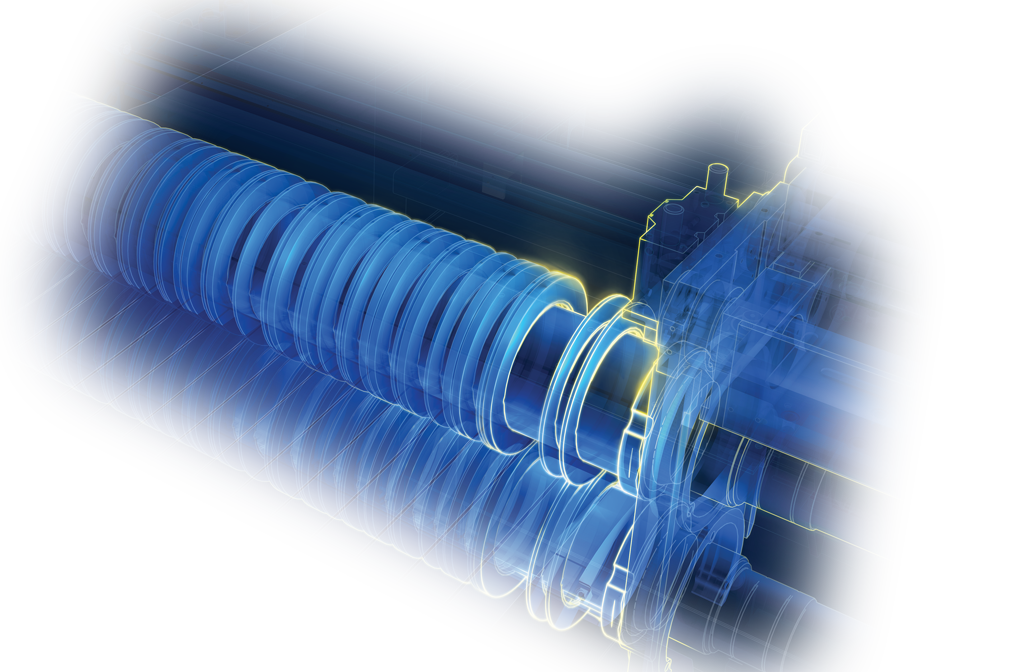

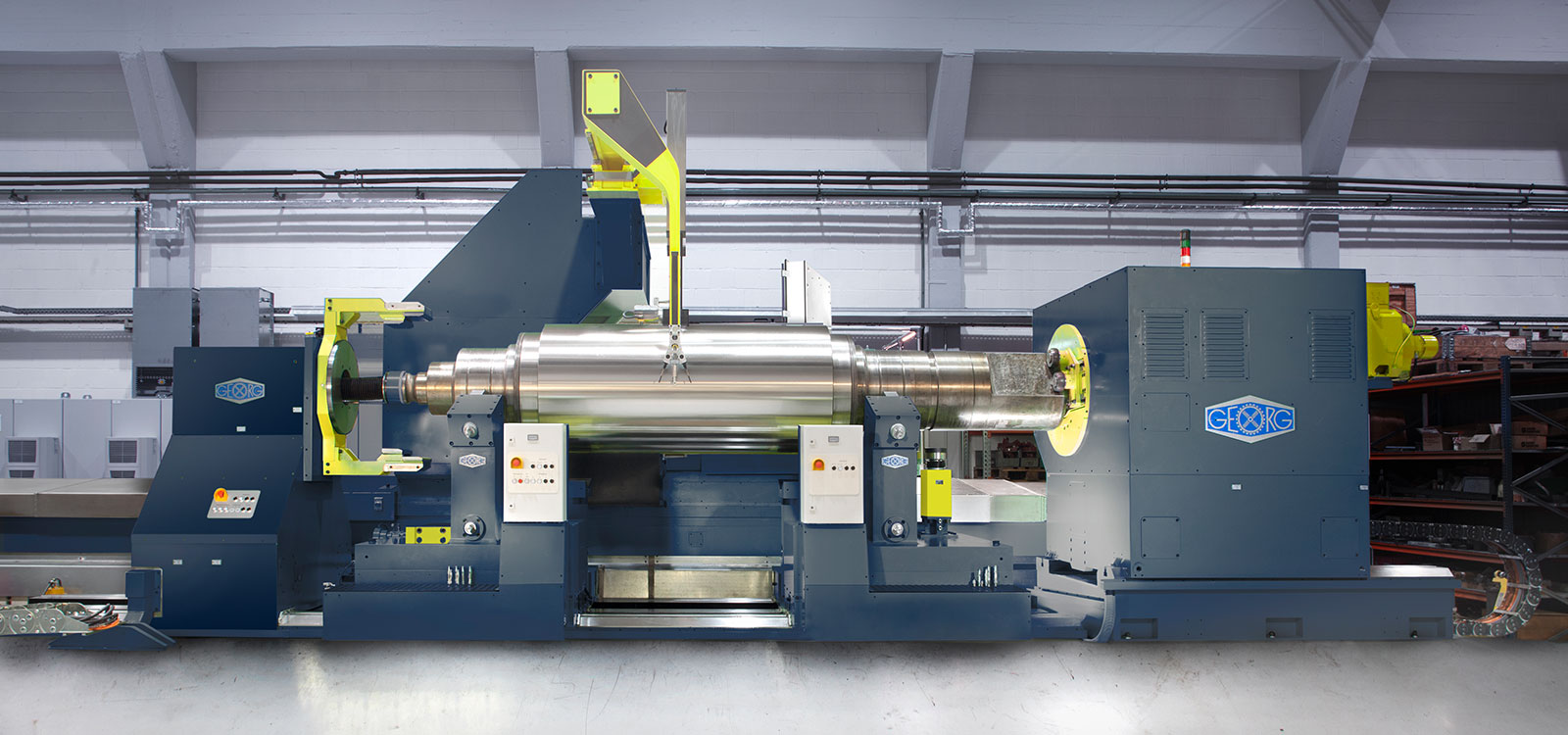

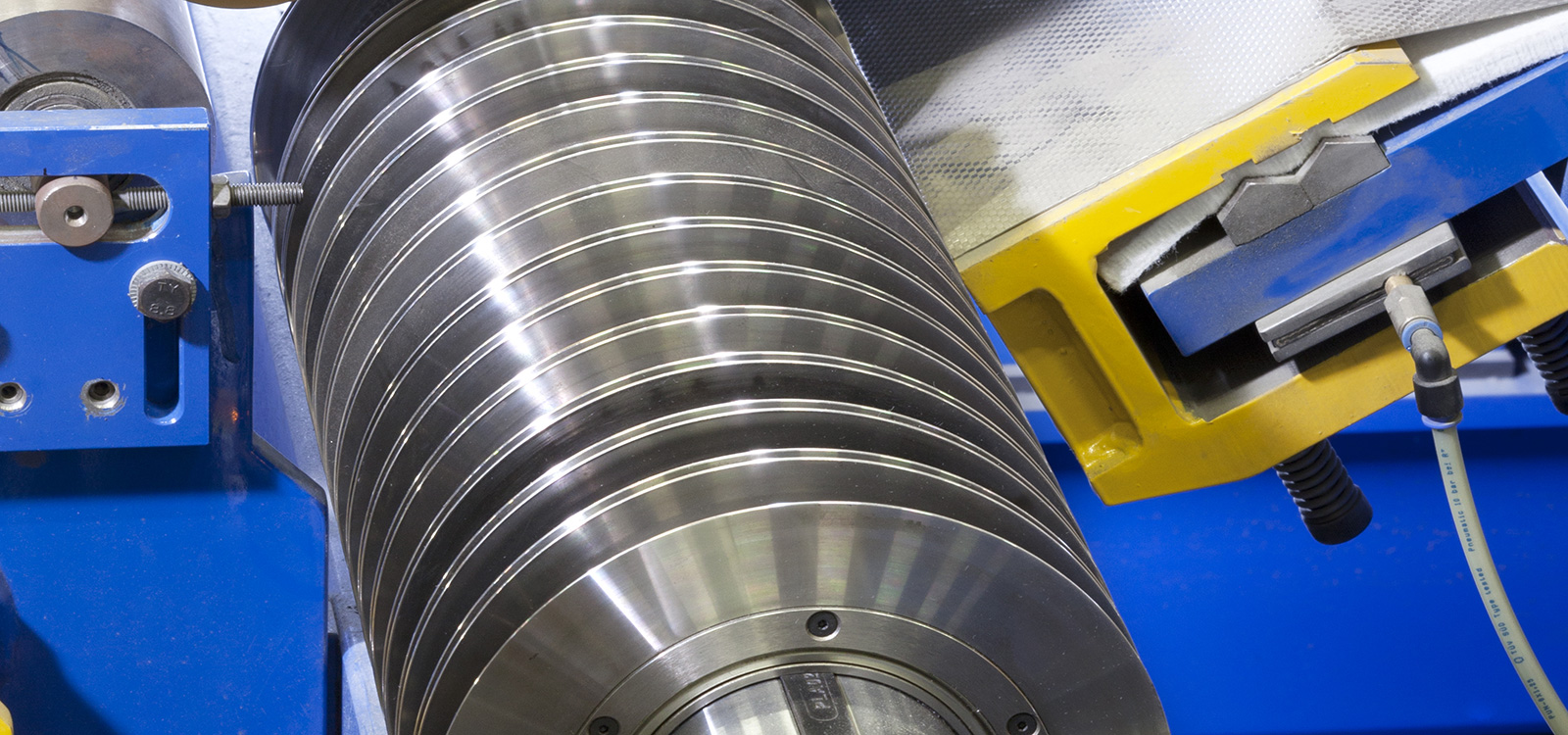

GEORG ultragrind

Roll grinding machines

- Highest accuracy for grinding back-up and work rolls

- Integrated measuring system

- Integrated GEORG smartcontrol

Workpiece weight

max. 25 t

Roll diameter

max. 1,500 mm

Roll length

max. 6,000 mm

GEORG precisionslit

Slitting lines for GO / NGO electrical steel

- Highest capacity

- Highest flexibility

- Highest automation combined with highest accuarcy

Coil weight

of up to 6 t / 30 t

Strip width

of up to 1,250 mm / 1,650 mm

Line speed

of up to 140 m/min / 400 m/min

Strip thickness

from 0.10 mm up to 0.65 mm / 1.00 mm

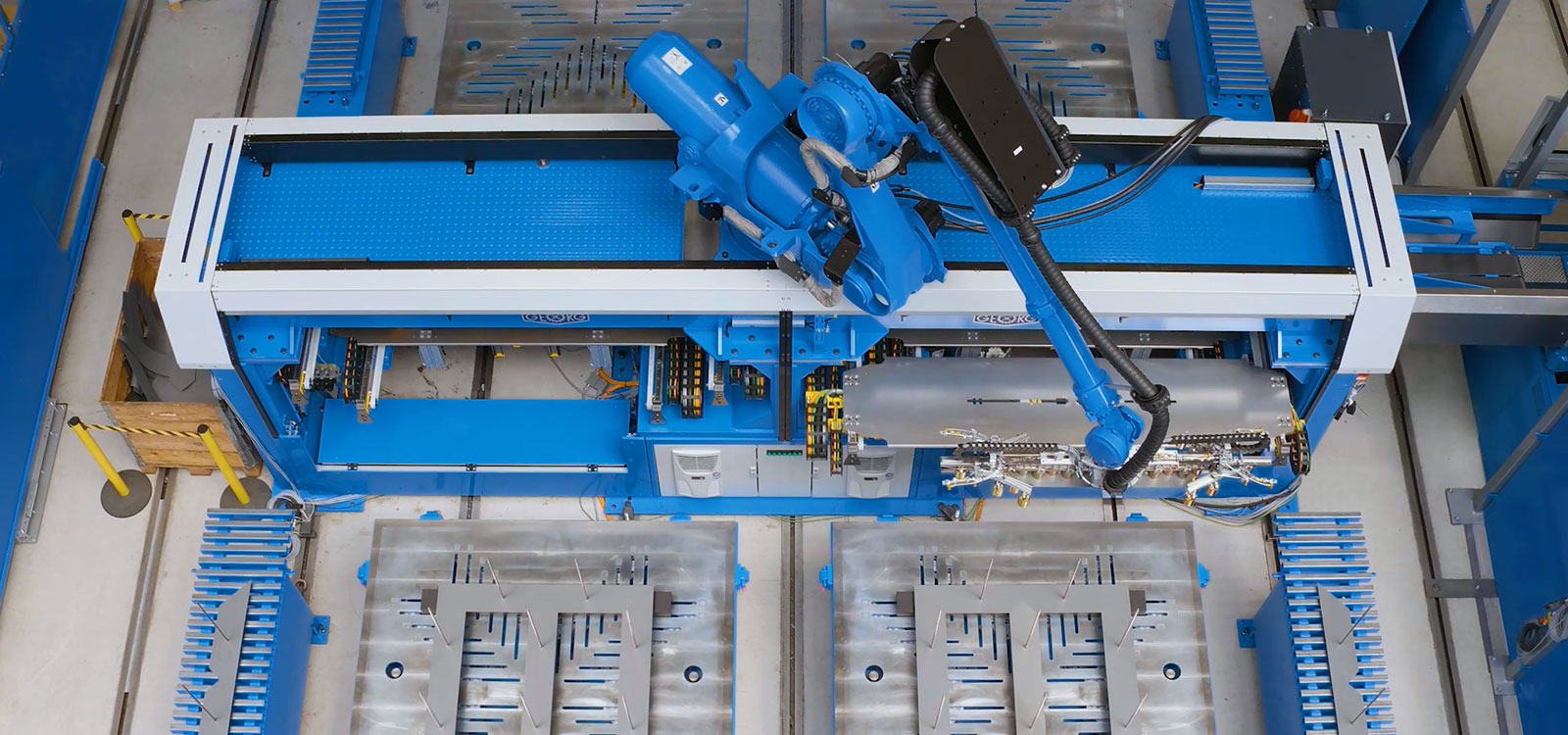

GEORG precisoncut TBA

Cutting lines for core laminations

- Up to 2 robots for high output

- Low burr, low loss quality lamination for high quality transformer cores

Strip Width

max. 400 – 1,200 mm

Line Speed

max. 240 m/min

Sheet length range

max. 2,000 mm

More Value

GEORG product

- Increase in profitability

- Increase in process reliability

GEORG protectionworld

- Reduction of operationg costs

- Increase in the rate of return

GEORG consulting

- Expansion of competitiveness

- Technology optimization

- Process optimization

GEORG digital

- Predictive maintenance

- Condition monitoring

- IoT

- GEORG dashboard

Why GEORG?

- Decades of experience in electrical steel

- Achieving highest tolerances and quality requirements

- Highest productivity solutions

- Highest grade of automation with IoT applications

- Latest energy saving features

- Setting new standards for strip monitoring

GEORG experience

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/experience/2023/12/Vollautomatische_Putzeinrichtung/georg-experience-vollautomatische-rm_kachel.jpg)