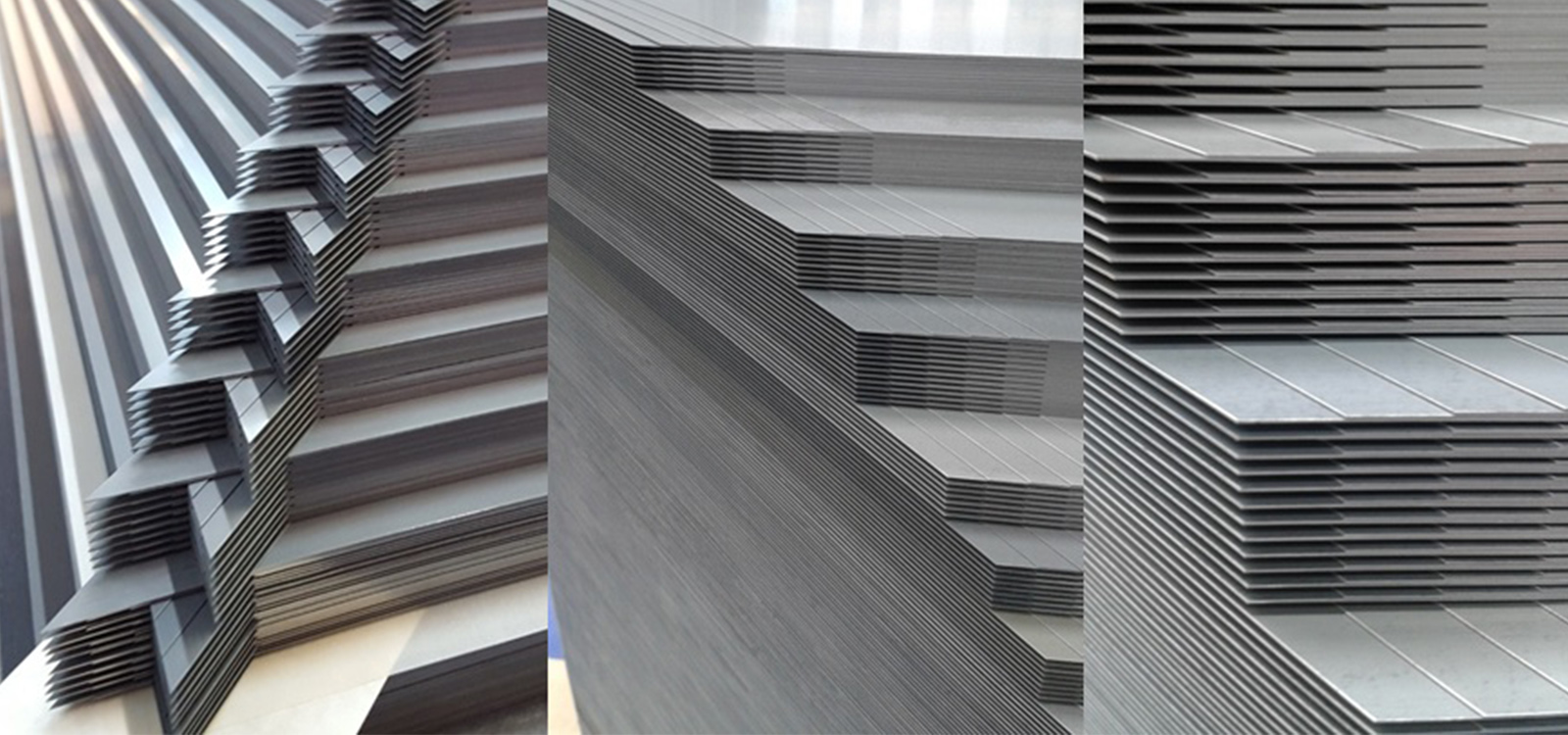

Automatic core stacking - high quality products

A key value for customers of automatic core stacking solutions developed by GEORG and Güdel is the consistency in quality. The automatic system will always ensure the same high-performance quality level, with much less dependence on personnel availability and worker skills. Automatic assembly systems already in operation at our customers’ sites have shown a reduction in core losses compared with manual stacking, greatly reducing the energy consumption for users.

Reports from various customers have shown that a reduction of no-load losses in transformers by up to 5% is possible by using automated core stacking solutions. Further, 5 to 10% less iron in the cores is needed compared to manual core stacking, which results in significant cost savings for core manufacturers.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/experience/2024/05/Technikunterricht.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/experience/2024/05/Annika_Becker.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/experience/2024/05/wohnzimmer.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/experience/2024/05/Niederhofer_berg.jpg)