2011

The GEORG Group purchases a neighbouring production site incl. 600 sqm of office space. Here the GEORG AUTOMATION GMBH will continue to grow and we will start offering our customers complete automation solutions including switchgear engineering.

2011

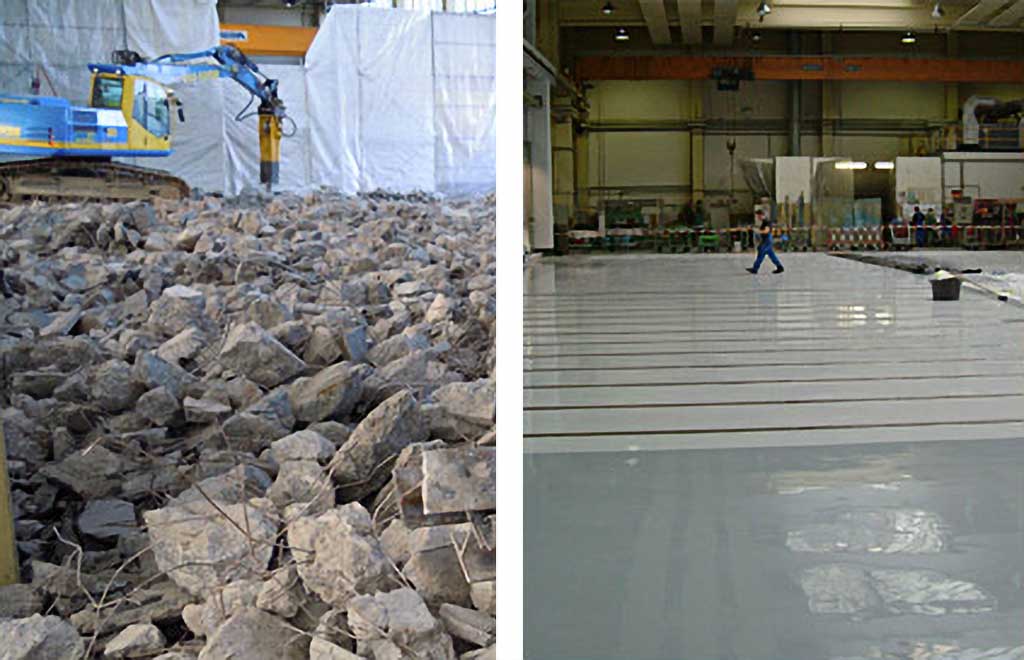

Modernization of the ground floors in the assembly halls of works II. During running production the ground floors are renovated and prepared for higher loads.

2012

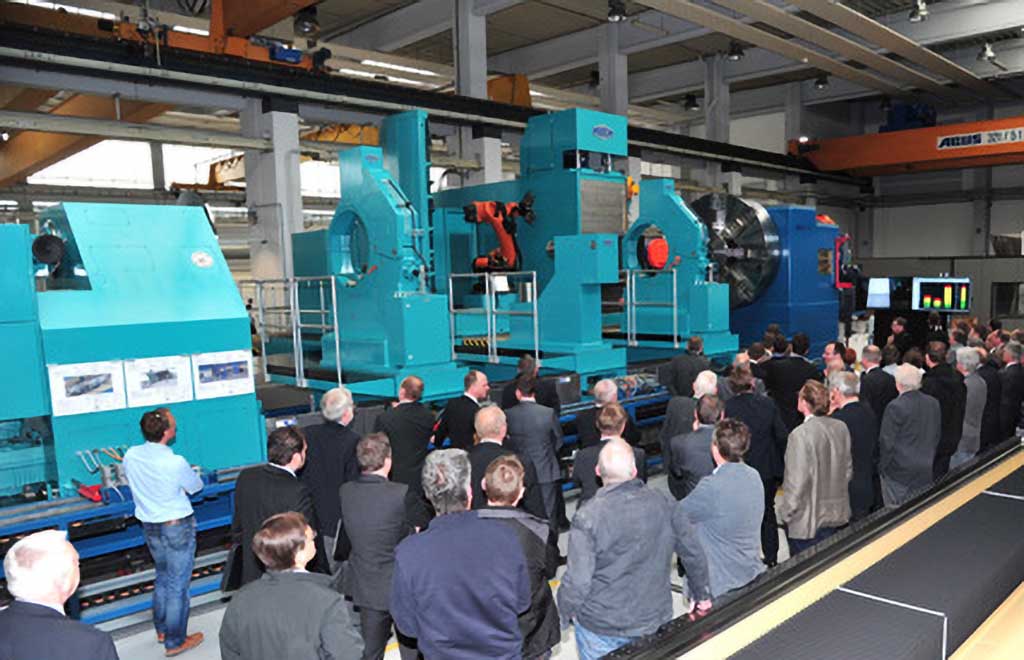

At the occasion of a customer day GEORG machine tool division presents the first GEORG ultragrind roll grinder.

2012

In this year we start with the construction of the new GEORGhouse.

2012

New investments are made in machinery of our manufacturing division.

New heavy cranes are invested in the assembly halls of our machine tool division.

2013

Our colleagues from finishing lines and machine tool divisions move into the new GEORGhouse where at the same time the GEORGacademy opens its doors.

In spring we have started our cooperation with the munical children day care located right opposite the GEORGhouse.

2014

GEORG is growing in all its business areas with regard to quality and quantity. (Large) orders from market leading companies e.g. for the world’s fastest edge-trimming line for can body stock (AluNorf, Germany), new roll grinding machine (Baosteel, China), slitting and cut-to-length lines for aluminium (KUMZ, Russia & ALNAN, China), GEORG precision cut TBA 1200 for the world’s biggest transformer producer (TBEA, China).

2015

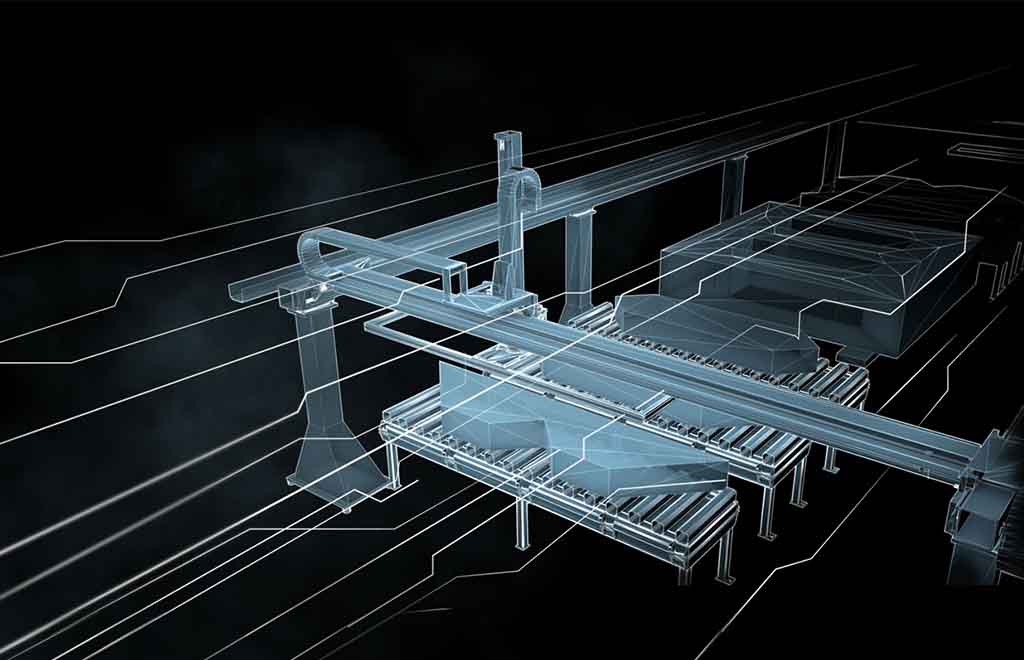

With this machining center GEORG is again setting new world standards. Turning, drilling, milling, grinding and exact measuring of large-size workpieces up to 250 to on one machine in one set-up.

2015

Introduction of a comprehensive service concept GEORG protectionworld.

Introduction, organization and marketing of various services.

2015

Enterpreneur award for GEORGacademy

Award received for the training concept established in 2014 as best-practice example within North-Rhine Westphalia.

2016

Take-over of the American machine builder Capco Machinery Systems Inc. and establishing the new company Georg Capco Inc. in Roanoke/Virginia, USA.

Establishing a common daughter company GEORG & UEBACH GmbH in Kreuztal for production of welded, bent, notched and laser-cut parts.

2016

Development and installation of the first GEORG roll grinder with CBN-technology in a hot rolling mill.

Inauguration of the worldwide first complete machining center for heavy workpieces with integrated 2-point measuring system (GEORG ultraturn MC) at Siemens Dynamowerk, Berlin.

2016

Further modernizations of our production machines in our own mechanical manufacturing workshop at our headquarter in Kreuztal.

2017

Inauguration of the third GEORG ultraturn MC at Doosan Skoda, Pilsen.

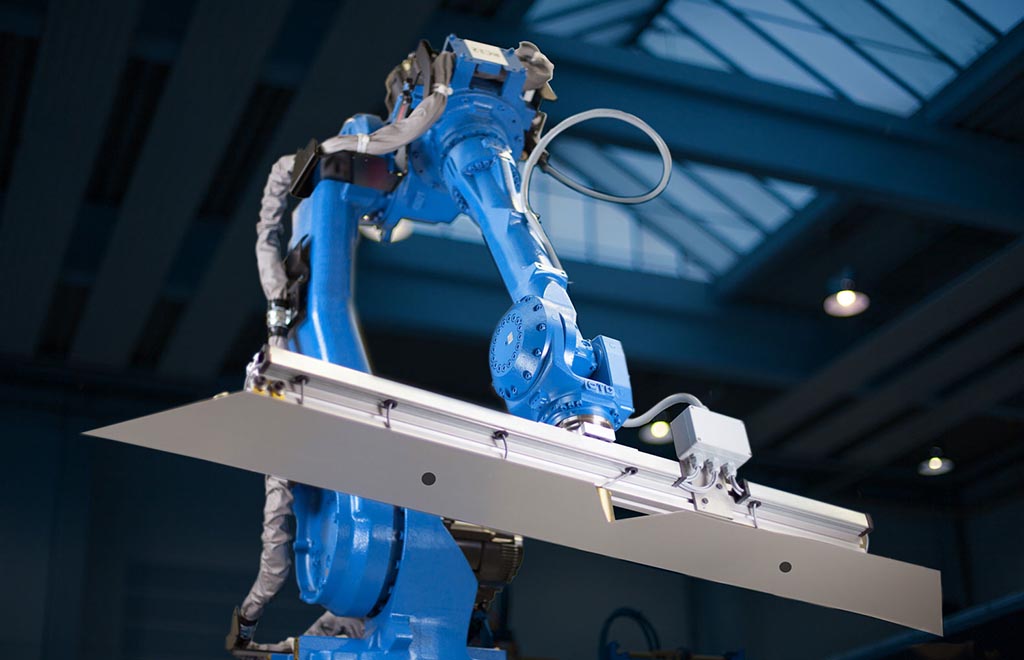

Introduction of the GEORG precisioncut TBA400 robot line – the first core cutting line for strip widths of up to 440 mm with robotic E-stacking systems.

2017

Entering a strategic partnership with the Swiss GÜDEL Group for common developments in the area of automatic core stacking technology for power transformers.

2017

Receipt of the so far biggest single order from a Chinese customer in our company’s history for our finishing lines division covering slitting and cut-to-length lines for aluminium.

2018

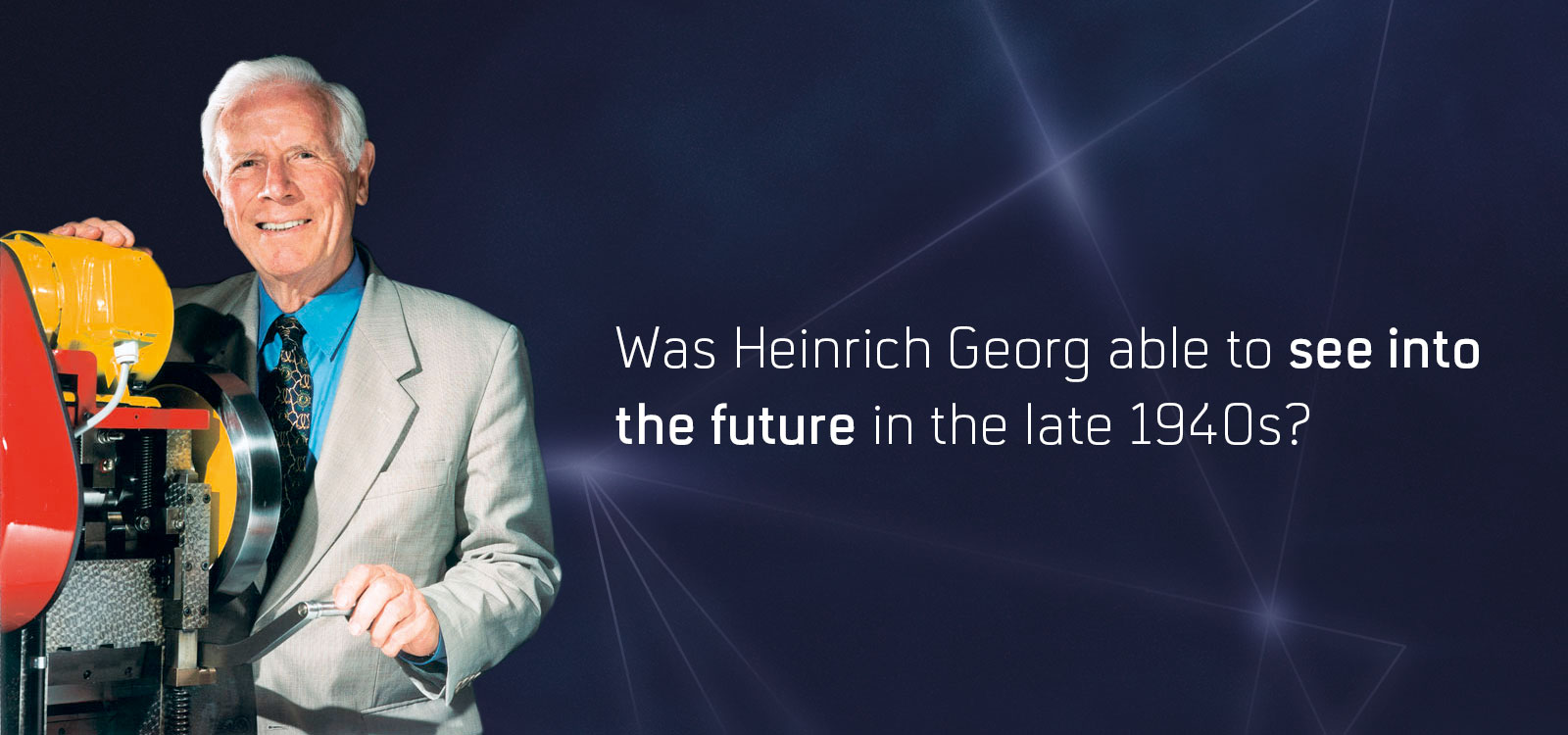

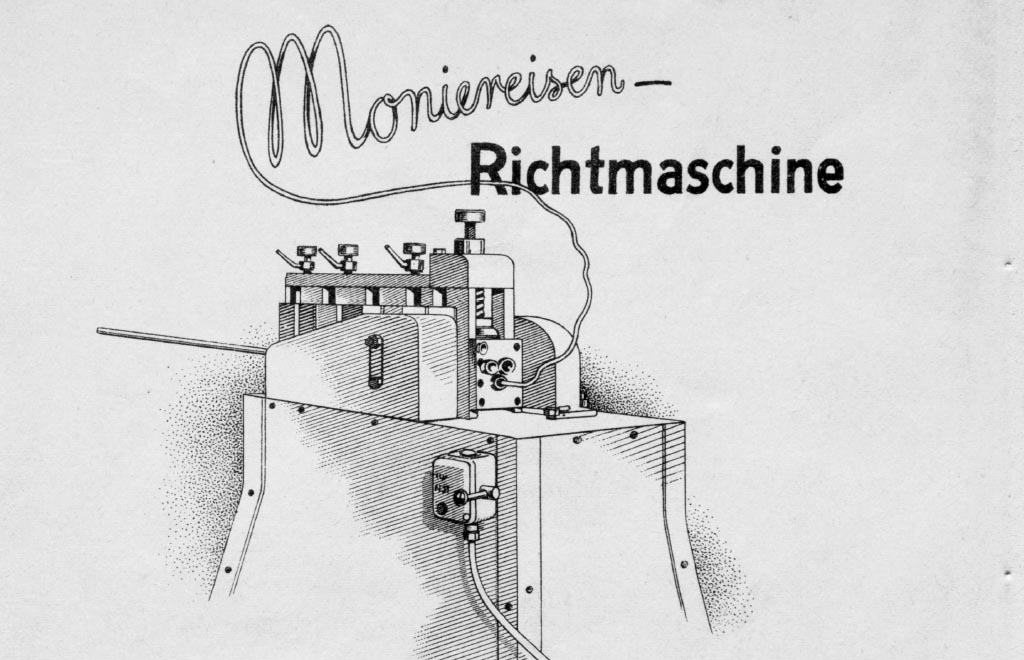

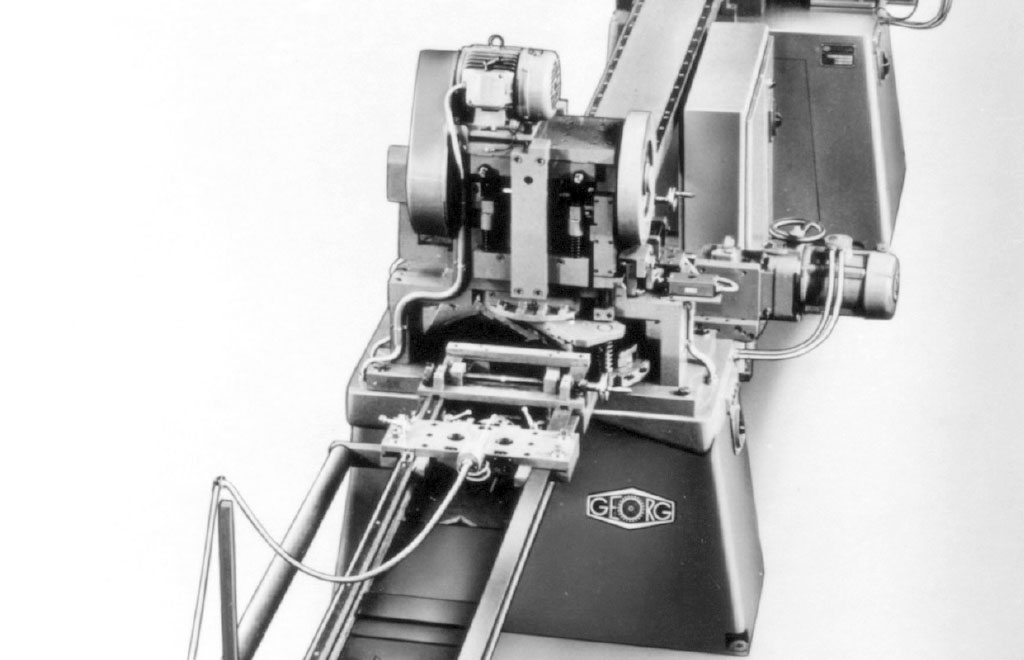

70th company anniversary - What started it all: Heinrich Georg's development of the Liliput shears

2018

70th company anniversary: The team from the very beginning.

2018

The anniversary year was celebrated as Oktoberfest with the employee families.

2018

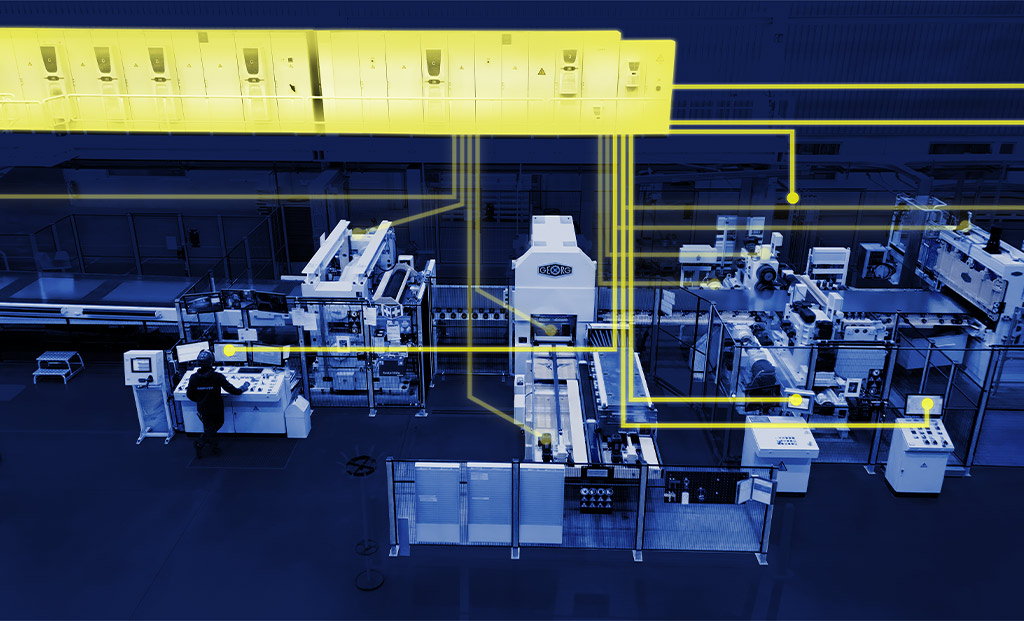

GEORG enters the way from a machine buílder towards an intelligent process optimizer.

All product units work with all efforts on new products and solutions. The developments are presented and discussed during a great customer day, the GEORG TechFair.

2018

GEORG Tech Fair: Numerous visitors from all over the world exchange ideas about the future of the digital age.

2018

Extension of the workshop in Plant 1: View of the expanded mechanical production on Siegener Straße

2019

The robot technology finds its way into the GEORG production systems for the transformer industry.

2019

The Business Unit Machine Tools enters the development and production of horizontal traveling column milling machines.

2019

At the EMO 2019, the latest innovations, the GEORG ultramill H and the GEORG smartcontrol, were presented to the interested trade audience.

2019

The digital twin in action.

2019

Move into the newly established, order-independent development department, GEORGinnovation.

2019

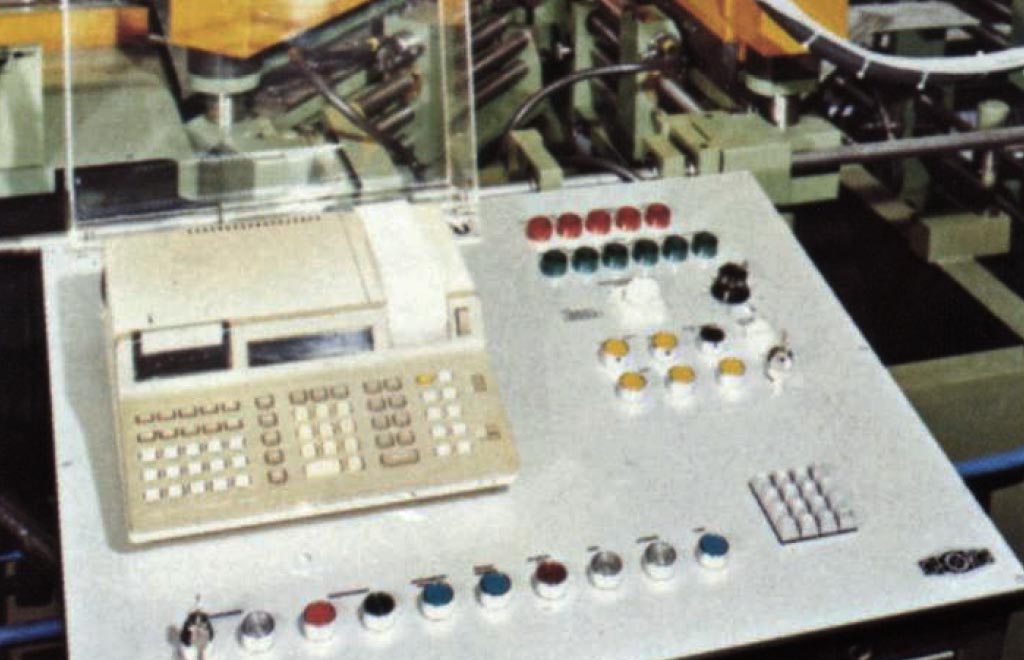

Development of the own GEORG control for grinding machines with world standard.

2019

GEORG receives several awards as a top employer in mechanical engineering.

2019

View into the parent-child office in the GEORGhaus.

2019

GEORG receives environmental award.

2020

The year of Corona pandemic

2020

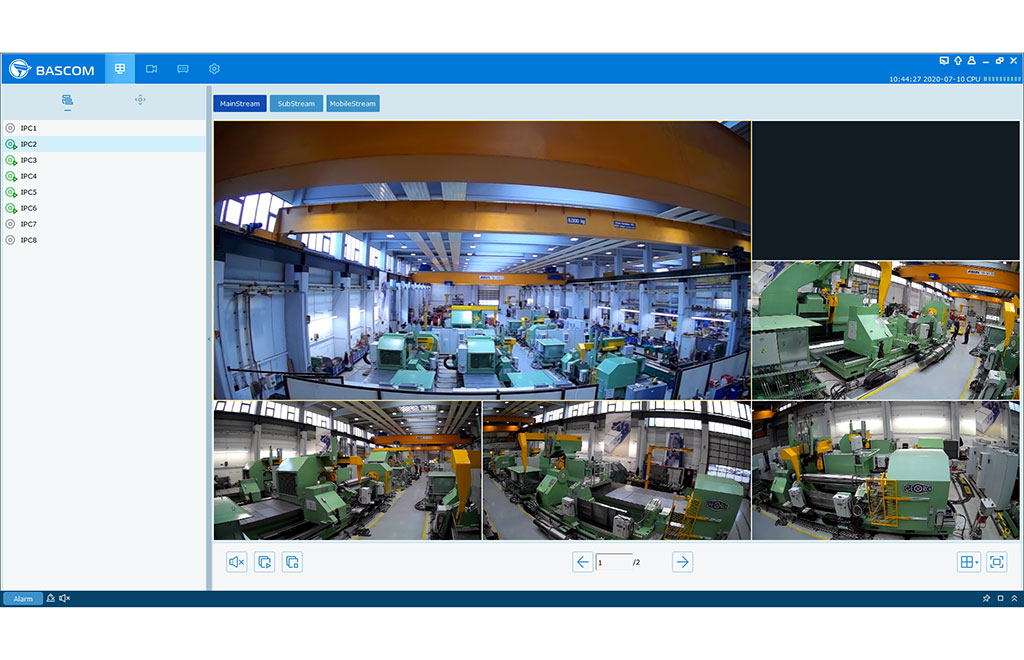

After virtual pre-acceptance, in-time delivery of five roll grinding machines with state-of-the-art control system GEORG smartcontrol for the Chinese Baowu Steel Group Corp., Ltd.

2020

Intensified investment in product development and digitalization.