GEORGcare machine tools

Time for the future

Well equipped

For your machine tools, our extensive service portfolio is now available to you with very short lead times thanks to capacities available at short notice.

This gives you the opportunity to carry out optimizations on your machines which are not or only with difficulty realizable in regular operation.

Our service technicians and engineers look forward to your challenges. No matter if it is a GEORG machine or a machine from another manufacturer: You benefit from our know-how and the usual GEORG quality.

Use the time to optimize your production with strategic and operative service measures and to prepare it optimally for the run-up.

We offer the following services at short notice:

- repairs, maintenance & inspections

- retrofit

- studies

trainings

Repairs, Maintenance & Inspections

More process reliability and efficiency

Increase the process reliability and efficiency of your lines with the high-quality GEORG inspections, maintenance and repairs.

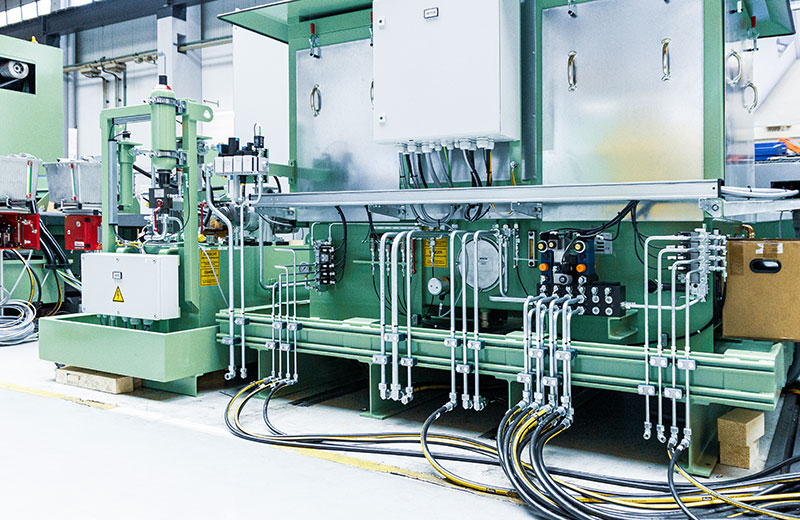

Thanks to the easing of travel restrictions, we are able to carry out trouble-shooting and repair work - such as the adjustment, cleaning and overhaul of hydrostatic systems - at short notice throughout Europe with a lead time of currently two days.

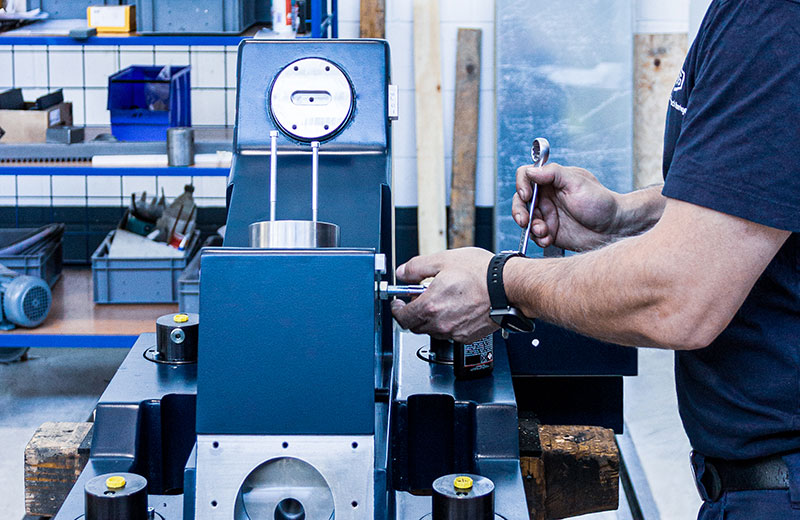

We can also carry out maintenance and inspections on your premises at short notice. We analyse your machine at your site and carry out a detailed inspection.

You will receive a detailed and structured inspection report according to your requests and objectives. This is a basis for further decisions regarding plant repair and/or optimization, with regard to plant repair and/or decisions regarding optimization.

After mutual agreement, we prepare an offer regarding repair, conversion or spare parts for you. Hereby, we also focus on your scheduling wishes with regard to implementation.

Of course, we also carry out minor maintenance and repairs of your machines, which are implemented at short notice and carried out according to expenditure.

Retrofit

Performance for your machine

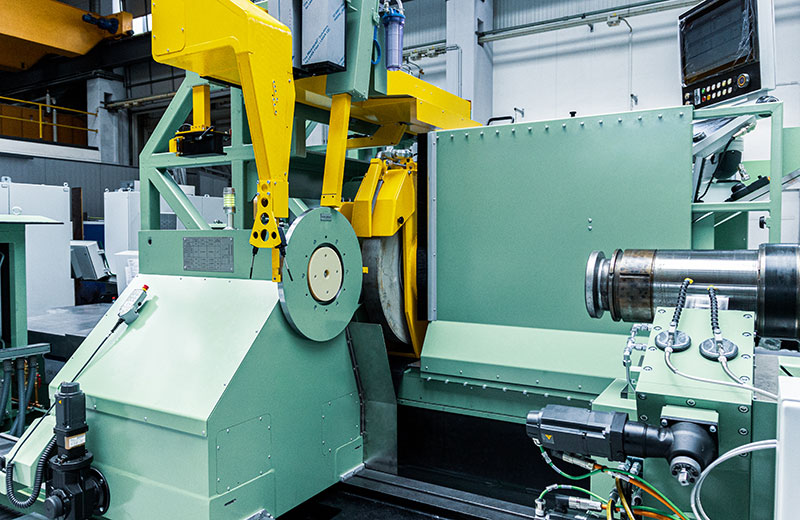

If your machines have already had several years of production, you do not need to say goodbye. In many cases, modernizing certain components and overhauling the machines is much more economical than buying a new one and ensures improved performance data and an optimal return on investment.

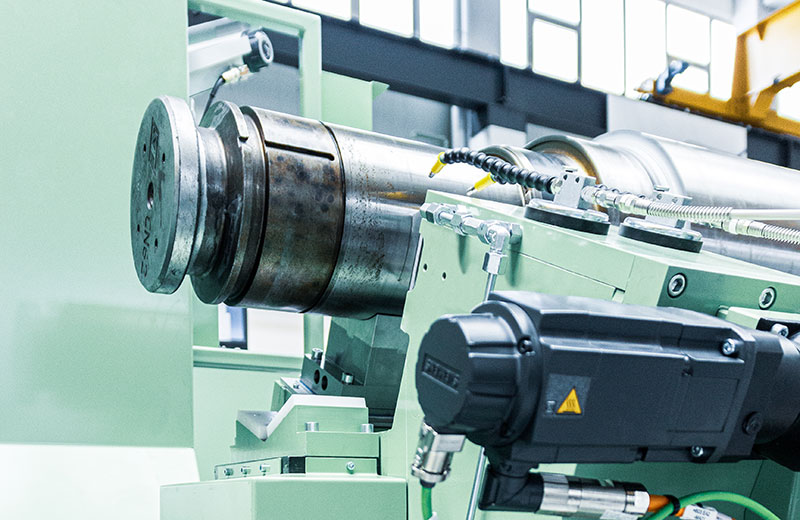

No matter if lathes or milling machines, GEORG multispindles, grinding machines (see also optimization of roll grinding machines) or single units: GEORG carries out retrofit projects in the most different versions on almost all machine tools of well-known German manufacturers.

The best results and a high degree of economic efficiency distinguish our projects in the most diverse degrees of complexity. We will be pleased to advise you right from the planning stage of your retrofit measures.

Retrofit with GEORG smartcontrol

The GEORG smartcontrol is one of the most modern machine control systems available on the market and part of our retrofit services (please see also Digital Twin/GEORG smartcontrol).

We integrate our control system in the course of modernization measures and can also implement further comprehensive mechanical and electrotechnical innovations on your machine tools in this process.

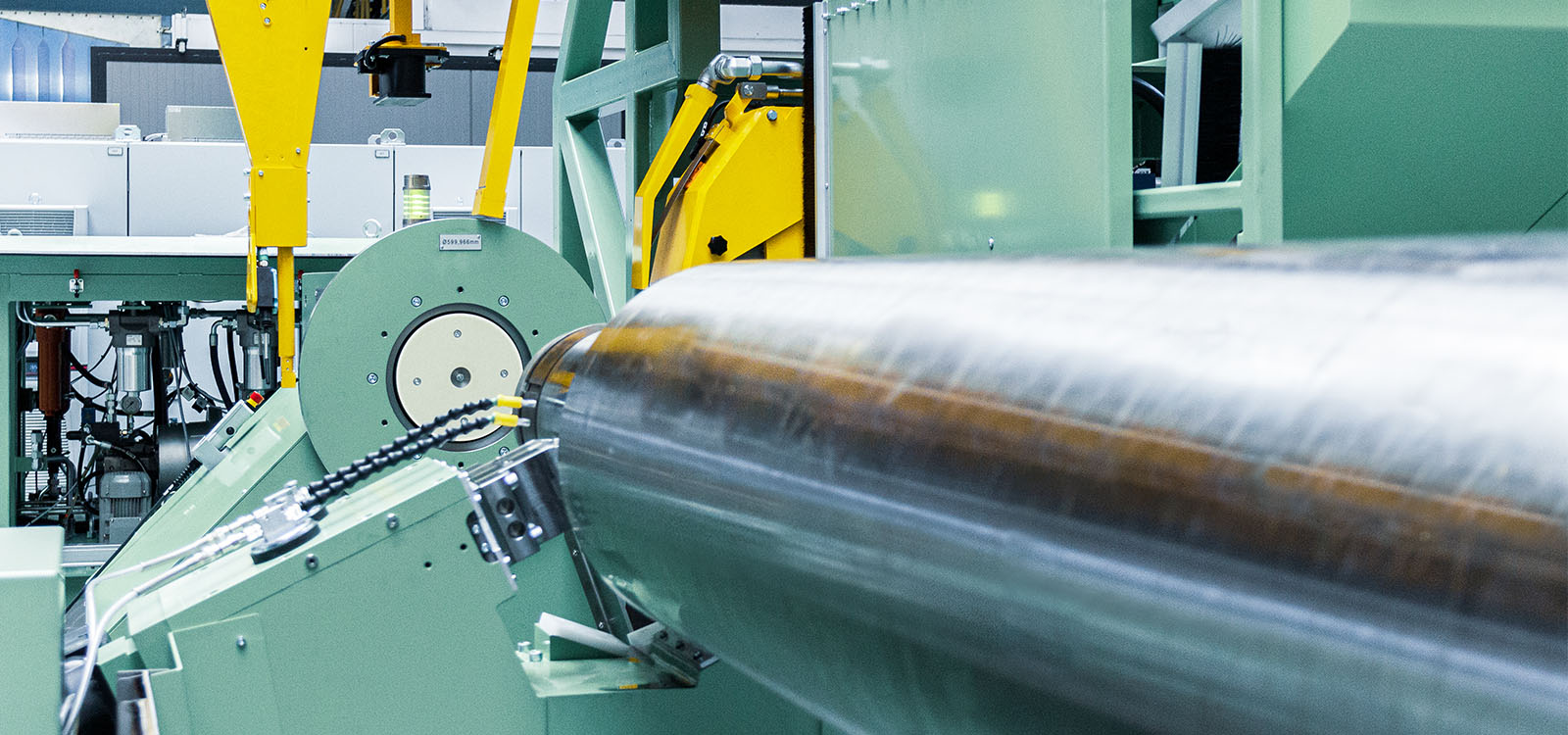

Optimization of roll grinding machines

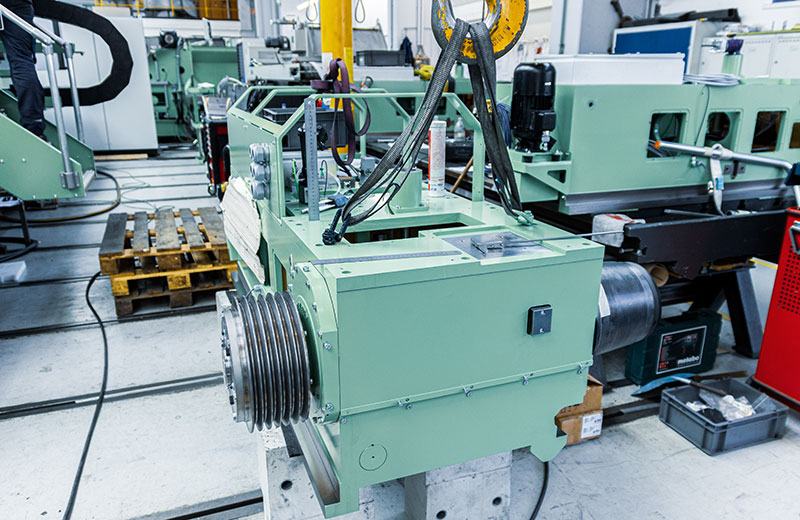

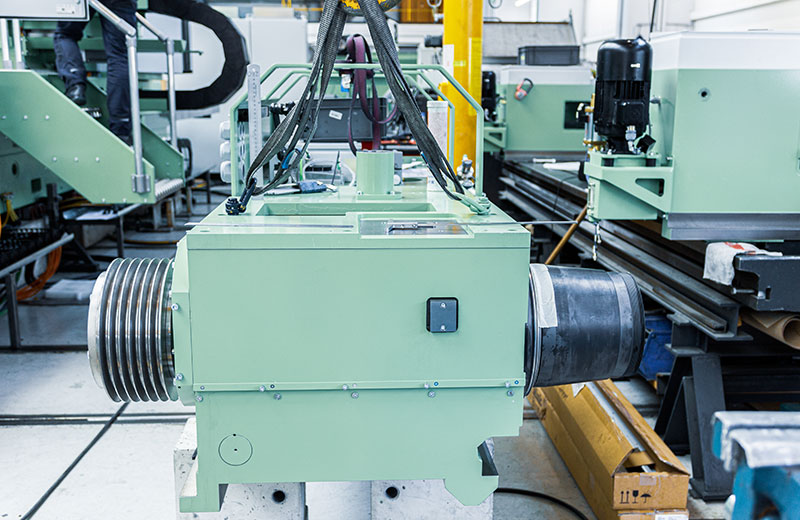

Especially in the field of roll grinding machines, we offer a comprehensive renewal and maintenance program, from the replacement of individual parts to the renewal of entire assemblies and systems. As usual with GEORG, we only use the highest quality parts and components as well as high-tech manufacturing and measuring equipment for best possible results.

Selection of our services:

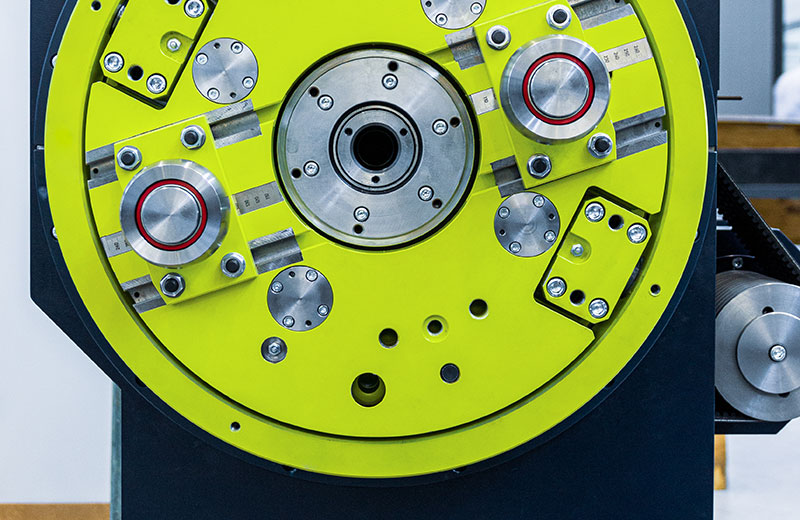

- Renewal of hydrostatic systems

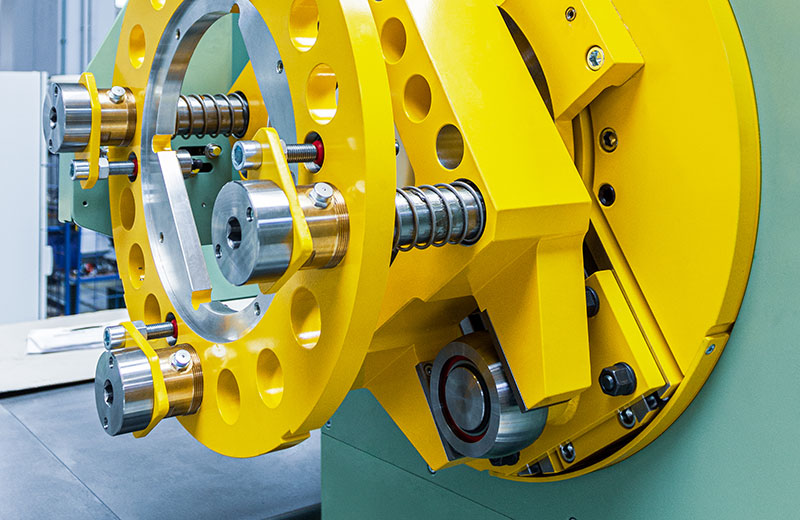

- Maintenance, adjustment and replacement of grinding axes and bearings

- Replacement of DC with AC motors incl. associated gearbox

- Modernization of complete feed axes

- Maintenance, replacement and modernization of measuring systems

- Renewal and replacement of slideway coatings (e.g. Turcite, Biplast)

- Upgrade to a new GEORG roll measuring system including workpiece testing technology

- Retrofit or exchange of assemblies such as headstock, tailstock, steady rest, grinding support, roll measuring system

- Complete renewal of the machine control and electronics (GEORG smartcontrol)

Individual consulting services:

- Optimization of your workflows by our experienced application engineers

- Programming of individual grinding programs

- Optimization of existing grinding programs

- Selection of the grinding wheels optimally suited to the application

- Time studies

Studies

Basis for your investment decision

How do you increase your productivity? What contribution do your existing machines give? And how confident are you in your investment decisions?

The proven, independent GEORG studies in the fields of design, production, automation and logistics provide you a sound basis for your investment decisions:

- Recording of the actual state of the machine

- Recording, summary and description of existing problems on the machine

- Determination of objectives with regard to your future ideas and according to the wishes of the customer

- Determination of weak points of the existing machine

- Analysis of time games and "bottle-neck" in terms of productivity

- Development of optimization proposals after joint coordination

- Preparation of offers according to your specific requirements and wishes

Trainings

Equipment for your machine operators and maintenance staff

State-of-the-art machine technologies, modernized and optimized machines - these are the foundations for more productivity and efficiency. However, you can only get the most out of your machines if your operators and maintenance staff are well trained.

That's why you should take advantage of the varied training programs offered by our in-house academy. The experts of the GEORGacademy will also be pleased to prepare the training courses according to your individual needs.

These can be carried out directly at your plant or in our modern training rooms at GEORGacademy.

Why GEORG?

With us, you have a service partner, which offer all competences consolidated:

- High quality

- Technologically advanced and

- Pragmatic solutions at the same time as well as

- Short reaction times

Above all, we think from an entrepreneurial point of view and look for your objectives the best solutions. Convince yourself and contact us.