GEORG Oficina de prensa

Milling machine for aluminium plates sets new standard

Highly automated system cuts machining time by more than 30 percent.

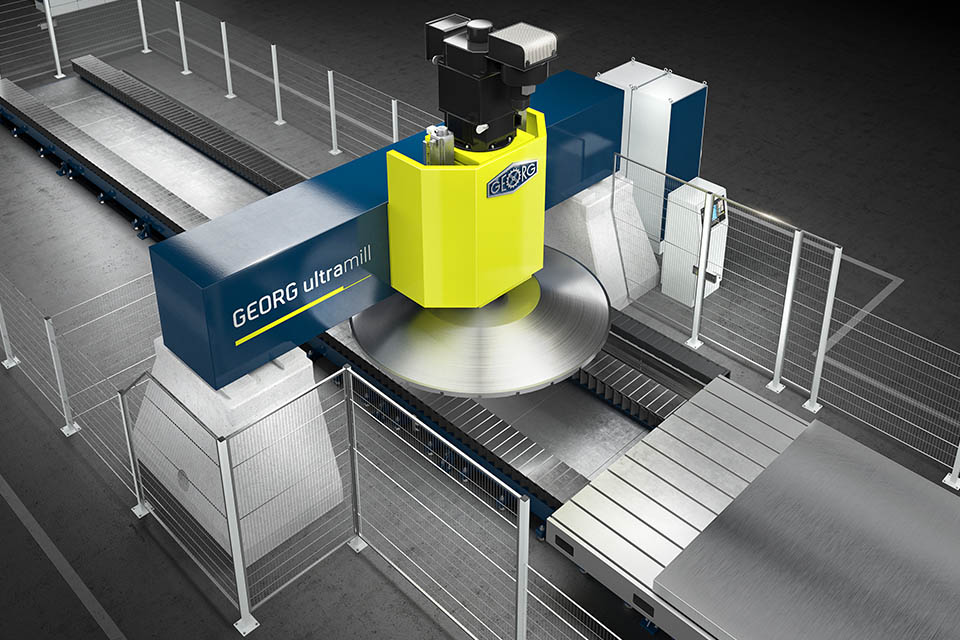

At the Aluminium 2018 show in Düsseldorf, GEORG is going to introduce its new portal-type milling machine – GEORG ultramill – for high-precision aluminium plates. With an accuracy of surface parallelism of +/- 0.05 mm achieved by this machine, GEORG is setting a new standard.

Kreuztal, Germany, September 3, 2018 At the Aluminium 2018 show in Düsseldorf, GEORG is going to introduce its new portal-type milling machine – GEORG ultramill – for high-precision aluminium plates. With an accuracy of surface parallelism of +/- 0.05 mm achieved by this machine, GEORG is setting a new standard. At the same time, production throughput increases significantly as GEORG has doubled the machining speed and implemented a high degree of automation compared to machines generally in use so far.

The new machine mills the surfaces of up to 3,000-mm-wide aluminium plates with a unique precision of surface parallelism. While +/- 0.1 mm used to be the industry standard, the new machine achieves an accuracy of 0.05 mm. In a single run – without rough and finish machining – it provides a surface roughness Ra between 0.28 and 0.4 µm.

With milling speeds of up to 4,000 mm/min and feed rates of up to 60 m/min, machining times are more than 30 percent shorter than those of conventional machines. This is enabled, among others, by the extraordinarily high milling unit drive power of 200 kW.

Also the high degree of machine automation has contributed to the marked increase in throughput: The plates are automatically fed into the machine, held firmly down by a vacuum clamping table, automatically turned over when the top side has been milled and again held down automatically by the vacuum clamping table while the other side is being milled.

Dr. Wieland Klein, Head of GEORG’s machine tools division, has already received feedback from users of the new machine. “First users of the machines have been reporting dramatic reductions in machining and non-productive times. And the product quality has become much better. Our preloaded and backlash-free, guideways guarantee highest precision and long-time accuracy of the machine.“

GEORG measures the plate thickness in three tracks by means of laser triangulation. The integrated GEORG Maintenance System (GMS) continuously monitors the complete machine, among others also the tool wear. The machine data is transferred to the host computer, linking the machine with the plant-wide process network.

At the trade fair, GEORG will also showcase a new portal-type milling machine that machines all sides of aluminium slabs with the slabs having to be turned only once during the process. Also this machine excels in terms of precision and provides very short machining times.

2.828 Caracteres, incluidos espacios y créditos