GEORGcare finishing lines

Time to care

The time is right

Use of the time to optimize your production with strategic and operative service measures and get ready for an optimum run-up.

The actual restrictions in mobility and contact only show little impact in our service operations. In the contrary as travel bans are going to be lifted more and more we are able to offer you our free capacities quickly with only short preparation times.

Once this should not be possible at your site, many requests can be settled thanks to modern telecommuncation via remote, Email or phone as well.

At present we can offer you the following services at short notice:

- Retrofit

- Inspection and maintenance

- Studies

- Trainings

Retrofit

New performance for your line

Quite often a well planned modernization of an existing line represents a worthwhile investment to reach a comparatively fast and sustainable result.

Our capacities with regards to retrofit, modernization and overhaul are not limited to our own products only but are available for other renown brands as well. So you can profit from the high GEORG quality even if you use other makers lines.

Here a selection of examplary retrofit measures available at short notice:

Retrofit of a CNC separation unit

- Even in other brands

- Production increase by saving set-up times

- Saving set-up operators

- Reducing injury risk

- Fast corrections

Retrofit of units (also for other brands)

- Mechanical and electrical modernization

- Sustainable usage of your investment goods

- Time saving by incorporation of existing elements

- High return on investment

- Saving resources

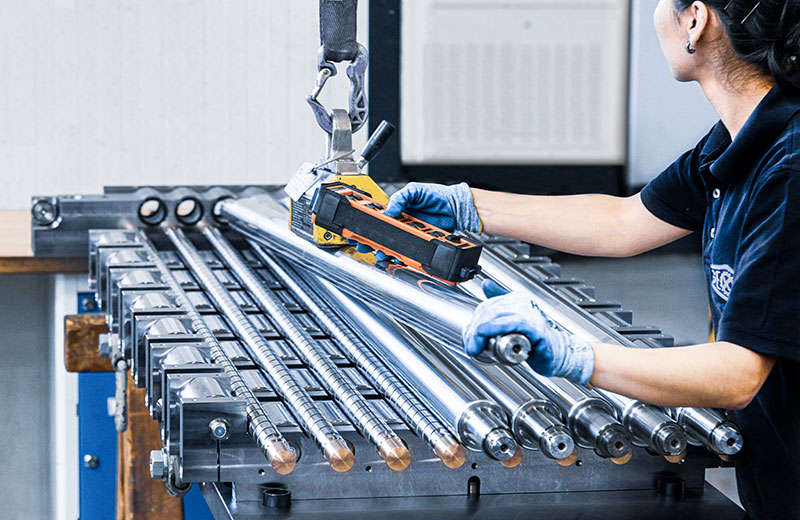

Replacement and repair of decoiler shafts

- Inspection, cleaning and maintenance of decoiler shafts

- Replacement of wear parts

- Complete replacement of decoiler shafts (even in other brands)

- Modernization to change-head design for different diameters

- Emergency repairs

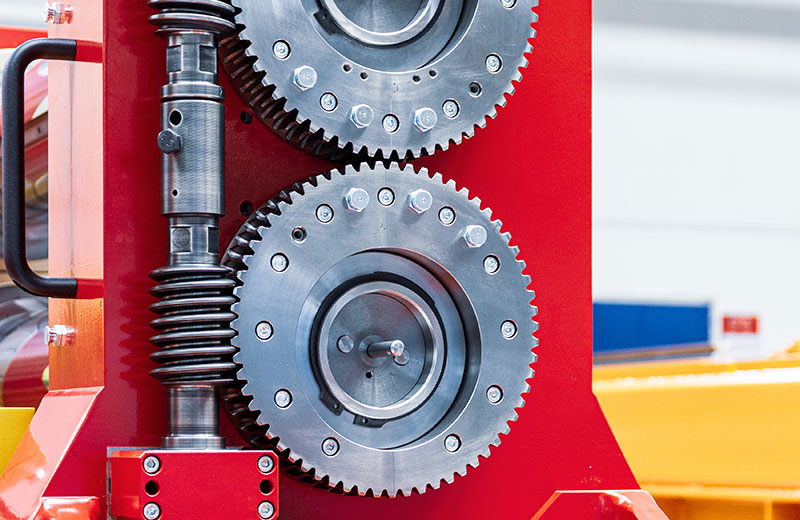

Overhaul/modernization of slitting shears (even other brands)

- Replacing new shafts

- New bearings

- New adjustment of cutter shafts

- New bushings in stands

- Change to hydraulic clamping system

Overhaul of leveling cassettes (even other brands)

- Examination and inspection

- Cleaning and maintenance

- Replacement of defective bearings and components

- Regrinding of leveling, intermediate and back-up rolls

- Adaption of revamped cassettes into your leveler

Inspection and Maintenance

Higher safety in process and efficiency

Increase process safety and efficiency of your lines by calling the high quality GEORG inspection and maintenance service.

We carry out a detailed examination and inspection of your line at site. As a result you will get a detailed structured inspection report forming the basis for further planning of repair, modernization or optimization schedule

Upon request we will work out a detailed spare parts offer in the scope of repair and modernization chosen by you.

Of course, we carry out maintenance work on your lines and will be glad to submit you a quotation.

Studies

Forming the basis for your investment decision

How can you increase your productivity? What is the contribution of your existing lines?

The proven, independent GEORG studies in regards to design, planning, logitics represent a profound basis for investment decisions:

- Examination of the actual status of the lines

- Listing and summarizing the present problems of the lines

- Finding a target how to fulfill your future plans

- Determining the weak points of the existing line

- Analyzing of time schedules and the “bottle neck“ in productivity

- Preparing optimization proposals in common consultation with you

- Establishing adapted quatations according to your requests

- Inspection report (Example) 470 KB Ver

- Study (Example, DE) 976 KB Ver

Trainings

The tooling for your line operators and maintenance team

Latest plant technologies, modernized and optimized lines – these are the basis for higher productivity and efficiency. However, only when your operators and maintenance engineers have undergone the perfect training, they know how to get the optimum results out of your lines.

Make use of the comprehensive training programme of our own academy. The experts of the GEORG academy will compose the individual training concept for your needs. This can either be carried out in our own modern trainining facility or at your site on your lines.

Why GEORG?

GEORG is your service partner who combines all competences under one roof for

- high quality

- high degree in technology

- tailored solutions

- short reaction times

However, what counts: We act as you think as entrepreneur and select the best solution to fullfil your target. Get convinced and get in touch with us.

Downloads

- GEORG Service Center for Shear Blades and Leveling Cassettes598 KB Ver