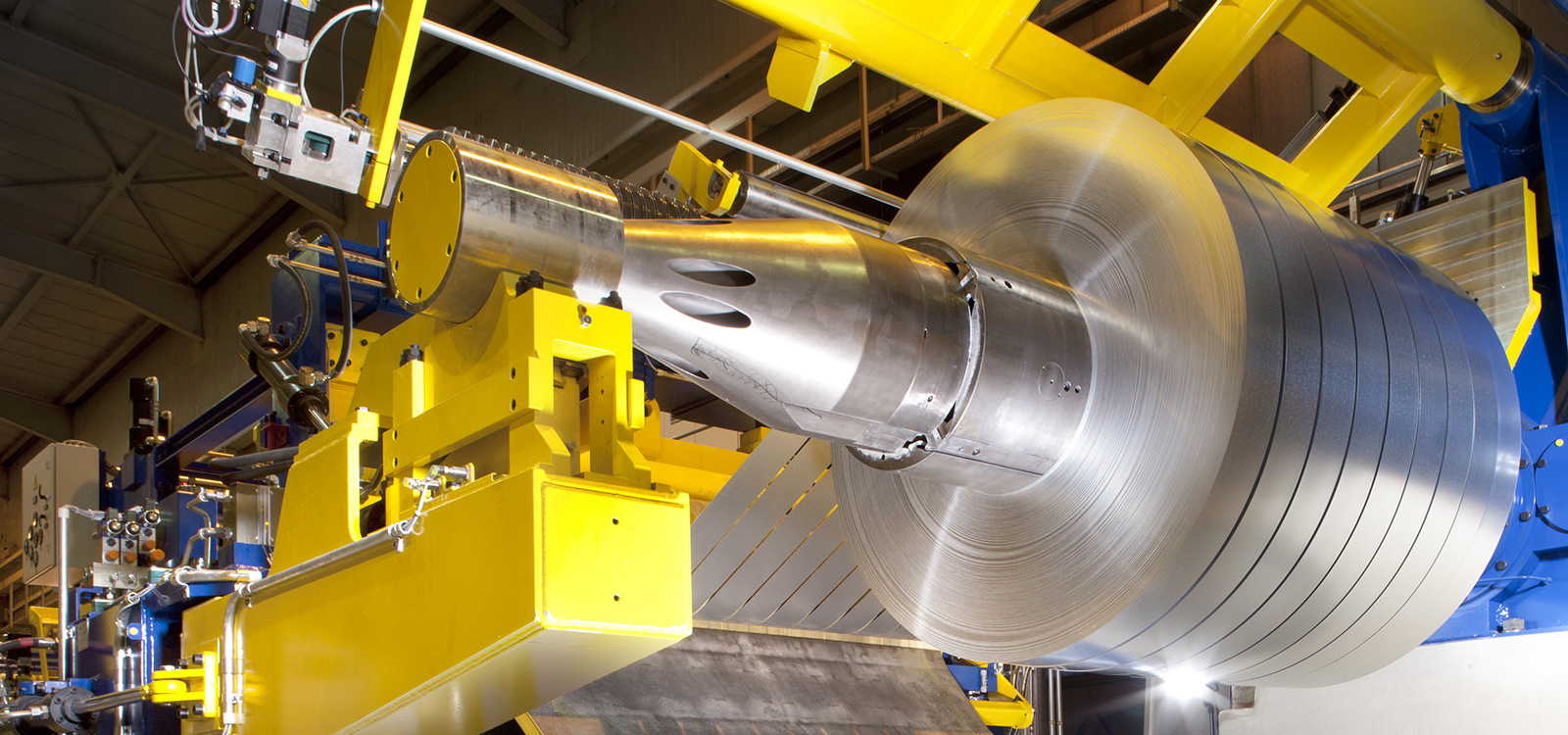

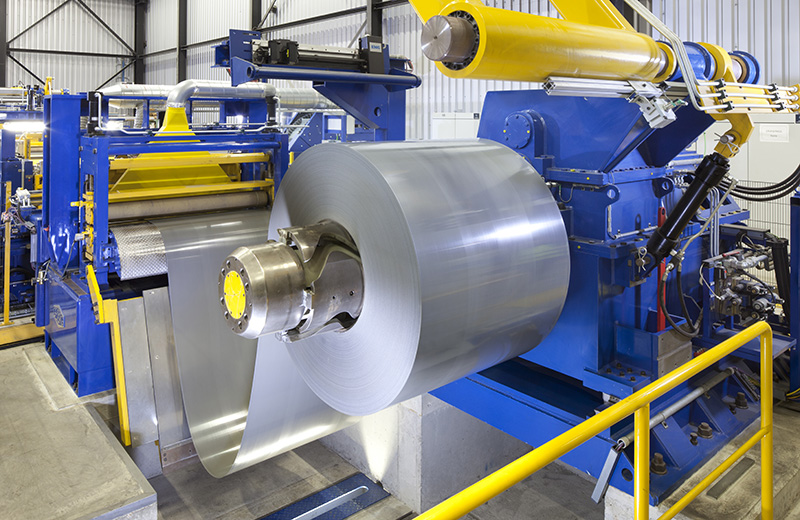

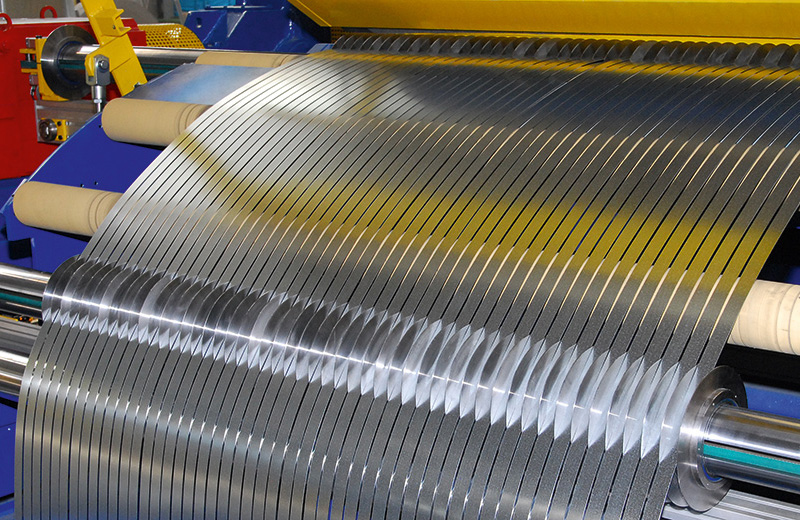

Single components for finishing lines

GEORG only uses high quality single components for their products. The production output of existing lines can be increased by integration of new components and additional aggregates in GEORG quality for higher profit. Also for existing lines we offer the optimum process results.